- HF Induction Brazing

- ┣━━ HF Induction Brass Solder

- MF Induction Forging

- Induction Hardening

- HF Induction Quenching

- HF Induction Annealing

- Induction Tempering or Preheating

- Induction Melting

- ┣━━ Rare Metals Melting

- ┣━━ High Capacity Melting

- Induction Shrink Fitting

- Induction Thermal Treatment

- Induction Heating for Aerospace

- Induction Bonding

- Induction Soldering

- Induction Welding

- Induction Jointing

- Other Induction Applications

-

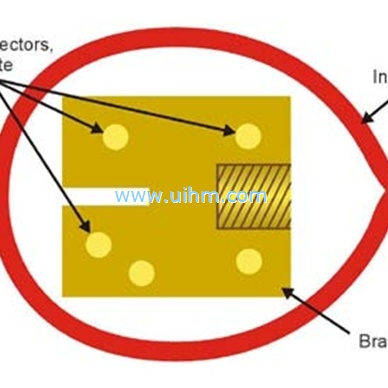

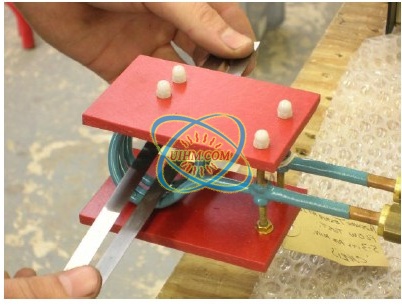

Induction Soldering Steel to Brass

ObjectiveHeat an assembly of small, gold-plated steel connectors to a brass block.Approx. 1/8” (3.2mm) diameter gold-plated steel connectors,1”(25.4mm) square x 1/4” thick brass block ,600F(315.6C),240 kHzTemperature,Frequency,Equipment6 kW induction he…

2006/03/28

-

Induction Annealing Stainless Steel

Induction Annealing stainless steel bread cutting saw bladesObjective: Anneal saw blades used for cutting bread, prior to hole punching.Material :.38” (9.6mm) wide and .51” (12.9mm) wide continuous strips of 400 series stainless steel.Temperature :600C (…

2006/03/28

-

Induction Shrink Fitting

Induction shrink fitting refers to the use of induction heater technology to pre-heat metal components between 150 C (302 F) and 300 C (572 F) thereby causing them to expand and allow for the insertion or removal of another component.Typically the lower t

2006/03/28

-

Induction surface hardening

Induction Surface HardeningKelvin Effect, Mean Curvatures and Load Impedance in Surface Induction Hardening: AnAnalytical Approach including Magnetic LossesAbstract– Kelvin effect (Skin effect) is used in surface hardening produced by induction heating of

2006/03/28

-

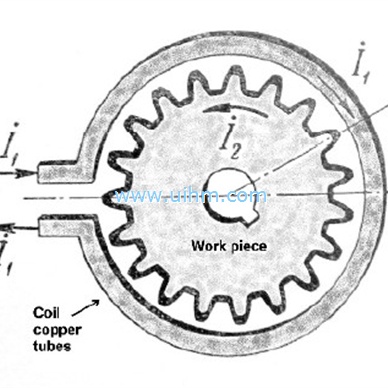

Induction Hardening Gears

In recent years, gear manufacturers have gained additional knowledge about how technology can be used to produce quality parts. The application of this knowledge has resulted in gears that are quieter, lighter, and lower cost, and have an increased load-c

2004/06/27

-

induction surface heating for turbing

induction surface heating for turbingOur UM induction heating machines meet the most diverse needs including those of:Steel, Foundry ,Chemical and petrochemical industry, Industry nuclear pressure vessels, Military Equipment, Materials Science and Space

2013/04/19

-

induction forging aluminum bar

As magnetic permeability of aluminum is not good as steel, when aluminum marterial is under induction forging work, it will need a bigger power machine than steel.induction forging aluminum bar

2013/04/04

-

induction melting Platinum

induction melting Platinum 1

2012/07/03

-

induction melting 20KG steel

Machine: UM-40AB-MFinduction melting 20KG

2007/08/02

-

This illustration shows how the connecting sleeve of a plate heat exchanger is inductively brazed on

This illustration shows how the connecting sleeve of a plate heat exchanger is inductively brazed on

2010/04/30

© Copyright 2025. uihm.com All Rights Reserved.