- HF Induction Brazing

- ┣━━ HF Induction Brass Solder

- MF Induction Forging

- Induction Hardening

- HF Induction Quenching

- HF Induction Annealing

- Induction Tempering or Preheating

- Induction Melting

- ┣━━ Rare Metals Melting

- ┣━━ High Capacity Melting

- Induction Shrink Fitting

- Induction Thermal Treatment

- Induction Heating for Aerospace

- Induction Bonding

- Induction Soldering

- Induction Welding

- Induction Jointing

- Other Induction Applications

-

Induction Heat Treatment Services

Induction-Heat-Treatment-ServicesShot blasting is creating depressions on the surface of a metal by regularly pelting it with shots of sand or steel balls of a certain diameter. The process is accomplished by employing something like an air gun. A shot bl

2006/03/30

-

Mult Induction Brazing Process

Brazing process exudes fumes, emissions and radiations that may be harmful for the people involved in conducting and managing. The people working in this industry are exposed to gases and harmful radiations that are exuded by the brazing of the base metal

2006/03/30

-

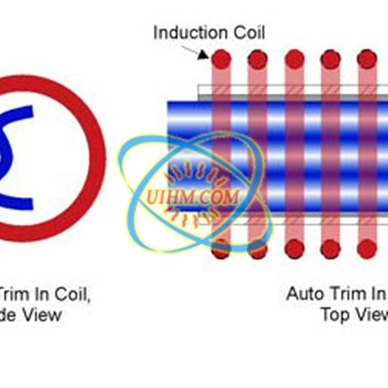

Induction Heating Aluminum Auto Trim

Objective :To heat various sizes of aluminum auto trim to 500F (260C) at a rate of 30 ft. (9.1m) per minute for curing an adhesive.Material: Magnetic steel and aluminum auto trim parts, coated with adhesive; 1.85” (47mm) ID ceramic tubeTemperature :500 F

2006/03/30

-

Induction Brazing a carbide to a stainless steel shaft

Objective : Brazing a cone shaped carbide to a stainless steel shaft for a diggerMaterial : Cone shaped carbide 1.12” (28.4mm) dia, 1.5”(38.1mm) tall,stainless steel shaft 1.12” (28.4mm) dia and various length, black brazing flux and braze shimsTemperat…

2006/03/30

-

introduction of brazing

What is brazing?The term “brazing” can be applied to any process which joins metals (of the same or dissimilar composition)through the use of heat and a filler metal with a melting temperature above 840 F (450 C), but below the melting point of the meta…

2006/03/30

-

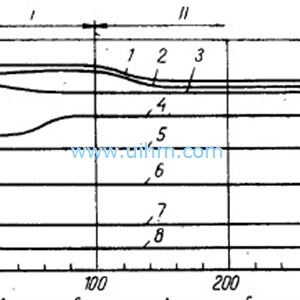

Effect of surface hardening by induction heating

Surface hardening of carbon steel by high frequency induction heating (HFIH) produces a considerable increase in its resistance to stress corrosion [1, 2]. The magnitude of this increase depends on the depth of surface hardening, on the strength of the sp

2006/03/28

-

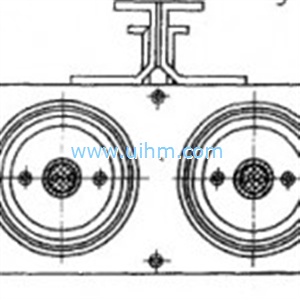

Induction Heating Billets

The induction heating of round bars and round-corner-square (RCS) billets are often treated as equivalent applications, even though they are not. This article reconciles recent theoretical and practical achievements in providing required heat uniformity w

2006/03/28

-

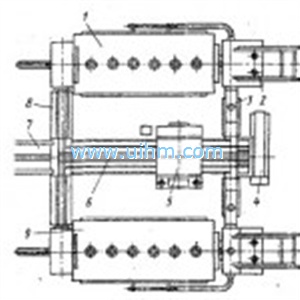

Heat Treatment

In recent years this plant is using hardening with preceding induction heating for morethan 50% of the total amount of heat-treated parts. These are mainly tractor parts made from45, 40Kh, 38KhGS, and 33KhS steels. The overwhelming majority of parts (85%

2006/03/28

-

Heat Treating Forgings

Forgings are subjected to final heat treatment or intermediate heat treatment to improve the maohinabitity.The processes that occur during heat treatment of forgings can be divided into two groups — processesoccurring at temperatures above and below Ac 3.

2006/03/28

-

Induction Heating Technology in aerospace

The purpose of this Tech Note is to demonstrate the advantages of Induction Heating technology like new Nova Star technology for precision induction heating applications. In each section, we will show how a particular aspect of this new technology makes a

2006/03/28

© Copyright 2025. uihm.com All Rights Reserved.