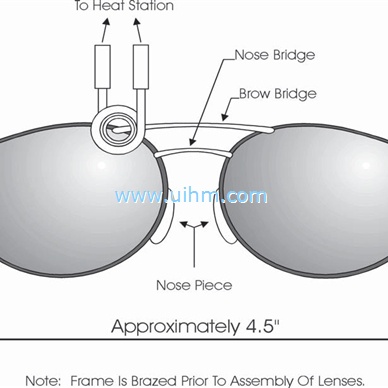

Induction Brazing aluminum tubing Class: HF Induction Brazing

Induction Brazing aluminum tubing Class: HF Induction Brazing Intro: Objective Heat aluminum for an automotive brazing applicationMaterial Aluminum tubing 0.50 (12.7mm) dia, an aluminum boss 1”(25.4mm) long, flux filled braze ringsTemperature 1200 F (649 C)Frequency 270 kHzEquipment •UM-UHF-10kW induction heating system, …

Induction Brazing steel mold Class: HF Induction Brazing

Induction Brazing steel mold Class: HF Induction Brazing Intro: Objective Heating steel golf ball mold to brazing dimple insertMaterial Golf ball mold 2” in diameter, braze flux paste, dimple insertTemperature 1400 F (760 C)Frequency 206 kHzEquipment • UM-UHF-20 kW induction heating system, equipped with a remote wor…

Induction Brazing copper joints Class: HF Induction Brass Solder

Induction Brazing copper joints Class: HF Induction Brass Solder Intro: Objective Brazing a joint between a copper lug and nickel plated copper pins on a pressurized heater connector.Material 1.5” (38.1mm) dia heater connector in a ceramic insulator with L shaped copper lugs and nickel plated copper pins, silver solder and br

Induction Brazing stainless steel joint Class: HF Induction Brazing

Induction Brazing stainless steel joint Class: HF Induction Brazing Intro: Objective Braze an end plug on a stainless steel joint of the car grill before powder coating applicationMaterial Stainless steel car grill 0.5” x 0.19” (12.7mm x 4.8mm), end plugs and braze ringTemperature 1350 F (732C)Frequency 267 kHzEquipment • UM-U…

Induction Brazing stainless steel hose to copper elbow Class: HF Induction Brazing

Induction Brazing stainless steel hose to copper elbow Class: HF Induction Brazing Intro: Objective Braze a stainless steel braided hose to copper elbows for a braided hose assembly.Material Stainless steel braided hose 3/8” (9.5mm) OD, copper elbow 1/4” (6.3mm) OD, braze preform rings and black fluxTemperature 1400 F (760 C)Frequency 267 kHz…

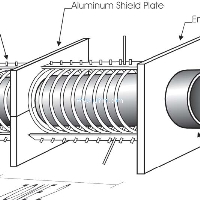

Induction Annealing steel tubes Class: HF Induction Annealing

Induction Annealing steel tubes Class: HF Induction Annealing Intro: Objective To heat steel tubes to 2000 F (1093 C) in an inert atmosphereMaterial 0.1” (2.54mm) diameter stainless steel tubeTemperature 2000 FFrequency 333 kHzEquipment • 10 kW induction heating system, equipped with a remote workhead containing one 1.0μ…

Induction Annealing Motor Shaft Class: HF Induction Annealing

Induction Annealing Motor Shaft Class: HF Induction Annealing Intro: Objective Annealing the end of a steel hydraulic motor shaft prior to machiningMaterial .75” (19mm) diameter steel rod, 6” (152.4mm) long with a keyway at the endTemperature 1350 F (732 C)Frequency 359 kHzEquipment • UM-06A-UHF induction heating system,…

Induction Annealing aluminum tubing Class: HF Induction Annealing

Induction Annealing aluminum tubing Class: HF Induction Annealing Intro: Objective Annealing aluminum fuel tank fill neck to 650 F (343 C)Material Aluminum fill neck 2.5” (63.5mm) diameter, 14” (35.5cm) longTemperature 650 F (343 C)Frequency 85 kHzEquipment • 40kW induction heating system, equipped with a remote workhead con…

Induction Annealing brass wire Class: HF Induction Annealing

Induction Annealing brass wire Class: HF Induction Annealing Intro: Objective Continuously anneal a brass wire used in electric motors at a rate of 16.4 yds (15m) per minute to eliminate work hardening caused during the drawing process.Material Square copper wire 0.06” (1.7mm) dia., temperature indicating paintTemperature

Induction Annealing aluminum lip Class: HF Induction Annealing

Induction Annealing aluminum lip Class: HF Induction Annealing Intro: Objective Annealing a 1” lip on aluminum cryogenic dewar that has been work hardened during the process of spin forming.Material Aluminum dewar, lip has a 3.24” (82.3mm) ID and is 0.05” (1.3mm) thickTemperature 800 F (427 C)Frequency 303 kHzEquipment •…

Recommended

induction brazing diamond segment

induction shrink fitting for Automotive cylinder rod

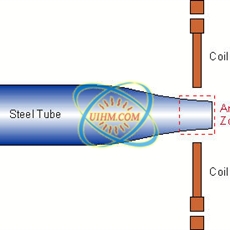

induction heating drill pipe by twin coils

Ball stud high-frequency induction hardening

Splined shaft induction hardening

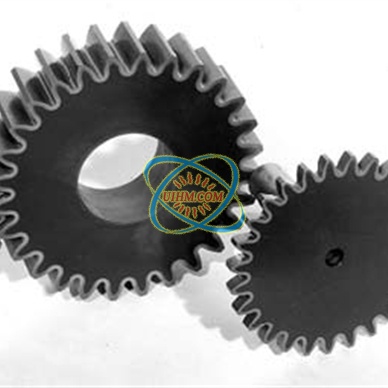

Sprocket induction hardening

Gear shaft induction hardening

High frequency induction brazing welding steel bar