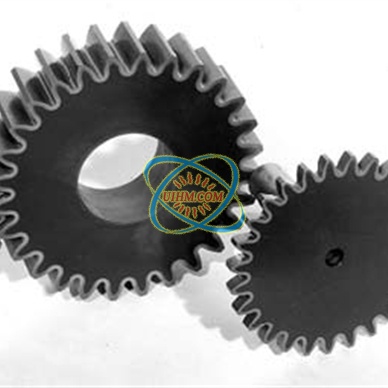

Induction hardening belt retraction gear Class: Induction Hardening

Induction hardening belt retraction gear Class: Induction Hardening Intro: Objective Heat the teeth of a soft steel seatbelt retraction gear to 1700F (926.7C) within two seconds for hardening.Material #4130 steel seatbelt retraction gears, water vortex quenching tank, electronically controlled air valves, adjustable timersTemper

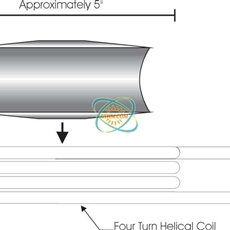

Induction Hardening bed knife blade Class: Induction Hardening

Induction Hardening bed knife blade Class: Induction Hardening Intro: Objective Harden a selected area on an 18″(457.2mm) bed knife blade for a reel type lawn mower. The hardness desired is between 45 to 55 Rockwell C, and should be measured 0.062″(1.6mm) from the cutting edge.Material 1070 Steel Bed Knife Blade measuring …

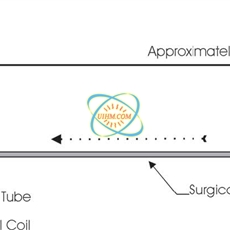

Induction Hardening Surgical Knife Blades Class: Induction Hardening

Induction Hardening Surgical Knife Blades Class: Induction Hardening Intro: Objective Harden a 4″(101.6mm) section of a Stainless Steel surgical blade measuring 7″ (177.8mm) long. Hardness should be 48 to 53 Rockwell C on the blade after processing.Material 420 Stainless Steel Surgical Blades measuring 7″(177.8mm)long, 1/4″(6.…

Induction Hardening Pulleys Class: Induction Hardening

Induction Hardening Pulleys Class: Induction Hardening Intro: Objective Heat cast iron pulleys to 1600F(871.1C) in order to achieve a hardness of 55 Rockwell C.Material Ductile Iron Pulleys measuring 3 1/2″(88.9mm) OD and 2″ (50.8mm) high.Temperature 1600F (871.1C)Frequency 164 kHzEquipment • UM-UHF-10 kW inductio…

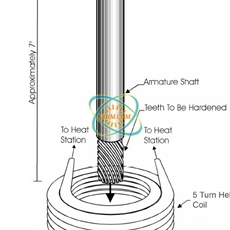

Induction Case Hardening Shaft Class: Induction Hardening

Induction Case Hardening Shaft Class: Induction Hardening Intro: Case hardening shaftsObjective Harden the gear end of an armature shaft to 58-65 Rockwell C at a depth of 0.02″(.51mm) on the center line of the teeth and to 49-55 Rockwell C at a depth of .010″ (.3mm) on the center line of the root.Material Steel armatu…

Induction Hardening Steel Cam Class: Induction Hardening

Induction Hardening Steel Cam Class: Induction Hardening Intro: Objective To harden the perimeter of ” thick steel cam assembliesMaterial ” thick steel cam assemblies of varying geometriesTemperature 1650 F (900 C)Frequency 177 kHzEquipment UM-UHF-20 kW, induction heating system, equipped with a remote heat station c…

Induction Hardening Steel Class: Induction Hardening

Induction Hardening Steel Class: Induction Hardening Intro: Objective To harden various size ends of hand held marking stamps. The area to be hardened is 3/4” (19mm) up the shank.Material Steel stamps 1/4” (6.3mm), 3/8” (9.5mm), 1/2” (12.7mm) and 5/8” (15.8mm) squareTemperature 1550 F (843 C)Frequency 99 kHzEq…

Induction Hardening steel screw threads Class: Induction Hardening

Induction Hardening steel screw threads Class: Induction Hardening Intro: Objective Heat steel roofing screw to 1650 F to harden the threadsMaterial Steel roofing screws of varying diameters less than 1.25” (31.75mm) diameter, 5” (127mm) longTemperature 1650 F (899 C)Frequency 291 kHzEquipment • UM-UHF-6 kW induction heating …

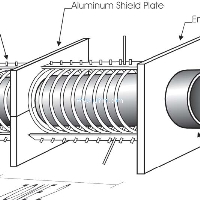

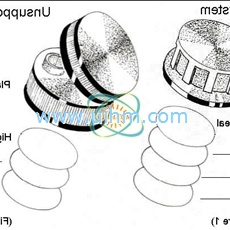

Cap Sealing With Induction Heating Class: Other Induction Applications

Cap Sealing With Induction Heating Class: Other Induction Applications Intro: Objective An induction heater is used to heat a polymer laminated aluminum foil in 0.5 to 2.0 seconds. The heat produced in the aluminum foil melts the polymer that bonds to the neck of a plastic container.Material Aluminum foil, polyethylene, polypropyle

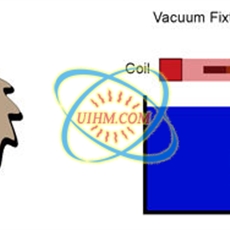

Induction Sealing Shampoo Container Class: Other Induction Applications

Induction Sealing Shampoo Container Class: Other Induction Applications Intro: Objective To heat an aluminum foil inside a plastic shampoo cap for sealingMaterial 2.0” diameter, plastic flip top cap, with a 0.9” diameter aluminum foil sealTemperature 250 – 300 F (120 – 150 C)Frequency 225 kHzEquipment UM-UHF-6 kW, induction heati…

Recommended

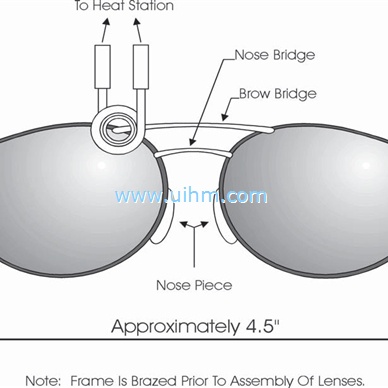

induction brazing diamond segment

induction shrink fitting for Automotive cylinder rod

induction heating drill pipe by twin coils

Ball stud high-frequency induction hardening

Splined shaft induction hardening

Sprocket induction hardening

Gear shaft induction hardening

High frequency induction brazing welding steel bar