parts of fully automatic induction machine Type:

parts of fully automatic induction machine Type:

Class: HF Induction AnnealingIntro: parts of fully automatic induction machine

induction annealing treatment Type:

Class: HF Induction AnnealingIntro: Annealing is a heat treatment in which material is exposed to an elevated temperature and slowly cooled. Annealing of the material changes physical properties of the material such as strength and hardness.UIHM induction annealing machines are designe

Induction Annealing Stress Relieving Type:

Induction Annealing Stress Relieving Type:

Class: HF Induction AnnealingIntro: STRESS RELIEVING,NORMALISING AND ANNEALINGStress RelievingStress relieving is applied to both ferrous and non-ferrous alloys and is intended to remove internal residual stresses generated by prior manufacturing processes such as machining, cold rolling an

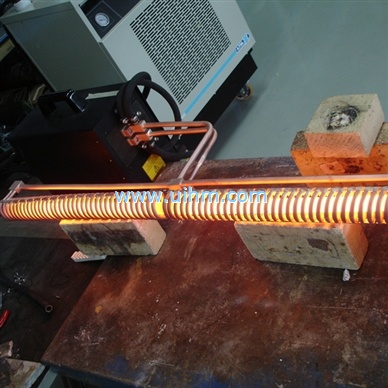

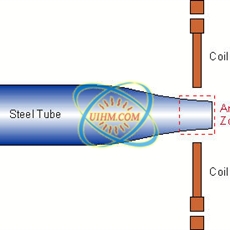

Induction Annealing steel tubes Type:

Induction Annealing steel tubes Type:

Class: HF Induction AnnealingIntro: Objective To heat steel tubes to 2000 F (1093 C) in an inert atmosphereMaterial 0.1” (2.54mm) diameter stainless steel tubeTemperature 2000 FFrequency 333 kHzEquipment • 10 kW induction heating system, equipped with a remote workhead containing one 1.0μ…

Induction Annealing Motor Shaft Type:

Induction Annealing Motor Shaft Type:

Class: HF Induction AnnealingIntro: Objective Annealing the end of a steel hydraulic motor shaft prior to machiningMaterial .75” (19mm) diameter steel rod, 6” (152.4mm) long with a keyway at the endTemperature 1350 F (732 C)Frequency 359 kHzEquipment • UM-06A-UHF induction heating system,…

Induction Annealing aluminum tubing Type:

Induction Annealing aluminum tubing Type:

Class: HF Induction AnnealingIntro: Objective Annealing aluminum fuel tank fill neck to 650 F (343 C)Material Aluminum fill neck 2.5” (63.5mm) diameter, 14” (35.5cm) longTemperature 650 F (343 C)Frequency 85 kHzEquipment • 40kW induction heating system, equipped with a remote workhead con…

Induction Annealing brass wire Type:

Induction Annealing brass wire Type:

Class: HF Induction AnnealingIntro: Objective Continuously anneal a brass wire used in electric motors at a rate of 16.4 yds (15m) per minute to eliminate work hardening caused during the drawing process.Material Square copper wire 0.06” (1.7mm) dia., temperature indicating paintTemperature

Induction Annealing aluminum lip Type:

Induction Annealing aluminum lip Type:

Class: HF Induction AnnealingIntro: Objective Annealing a 1” lip on aluminum cryogenic dewar that has been work hardened during the process of spin forming.Material Aluminum dewar, lip has a 3.24” (82.3mm) ID and is 0.05” (1.3mm) thickTemperature 800 F (427 C)Frequency 303 kHzEquipment •…

Induction Annealing Steel Wire Type:

Induction Annealing Steel Wire Type:

Class: HF Induction AnnealingIntro: Objective To heat 3” (76.2mm) from the end of the wire on a woven wire cloth 60” (1.52m) long. This prepares the wire mesh for bending in a press brake.Material Woven wire cloth (steel) made of 1/2” (12.7) diameter wire, 60” (1.52m) long. Wires are 1.5…

Induction Annealing copper tubing Type:

Induction Annealing copper tubing Type:

Class: HF Induction AnnealingIntro: Objective To heat both ends of a copper tube to anneal as soft as possible 1.5” (38.1mm) from end and retain full hardness next to annealMaterial 1.625” (41.275mm) dia x 24” (609.6mm) long copper tubeTemperature 1500 F (815.5 C)Frequency 70 kHzEquipment…