How Induction Brazing Works

Views Send Enquiry

Induction brazing is a process where two or more materials such as pipe are joined together with a molten space filler metal using an induction heating coil which delivers a very high temperature. The induction brazing process will involve temperature more than 840 centigrade degree but still it is have to below the temperature of the material (such as pipe). By the induction brazing process the join materials will have very strong permanent attachment.The technology of brazing process itself has developing nowadays. New products and techniques of this metallurgical joining are discovering to enhance the performance, quality and cost effective that includes induction brazing method. In the last decades, brazing products and methods have been developed, including oxygen-acetylene torches, controlled environment brazing furnaces and vacuum furnace brazing and induction brazing. Today, brazing is used in a broad range of manufacturing systems including refrigeration and air-conditioning, household utensils, tubular structures, automotive parts, tools and machinery, electrical components, nautical and aerospace equipment, farm implants, and business machines.Brazing, as people dealing with metals would know, is a process of joining metals (and non metals too.) There are different techniques for joining metals through brazing which are known as brazing processes but there is a common basic working principle for all these processes.Basic Brazing ProcessFor brazing, a Braze Filler Metal (BFM) is used. Most brazing filler metals are alloys, or combinations of pure elements or materials. The filler metal must have a melting temperature above 840 centigrade degree but below the melting point of the base metals or the metals that need to be joined. In brazing process, the base metals are heated, generally to a point that is slightly above the liquidus (liquidus is the temperature above which an alloy is completely molten. When an alloy exceeds the liquidus temperature, there are no solid phases present.) of the filler metal, causing it to melt. As a result, the filler metal flows into the parallel joint clearance between the two base materials by capillary attraction and bonds to their surfaces through atomic attraction and diffusion. Thus, the basic principle through which brazing works is by joining the base metals by creating a metallurgical bond between the filler metal and the surfaces of the two metals being joined. However, there are certain differences in this basic technique of joining metals when we refer to different types of brazing processes.Brazing ProcedureFor an effective brazing, some conditions have to necessarily fulfilled. If not then problems associated with brazing occurs. Thus, the following conditions should be there:

Good fit and proper clearance

Clean base metals

Proper fixturing

Proper fluxing and atmosphere

Heating the assembly

Cleaning the brazed assembly

All these can be attained by following proper brazing procedure. To get step by step instructions about how to do brazing, read Basic Brazing Procedures To get the best quality and best cost effective brazing result is to have a best heating technique to ensure the best flow of filler metal in between the join of the material. In today demands the brazing process will also involve in a production line which a unique of brazing method is necessary to achieve best quality and cost effective. Therefore a unique induction brazing is widely using in such workIn induction brazing method temperature are usually reached in a matter of seconds for higher manufacturing productivity. The induction brazing method uses magnetism to induce electrical resistance to heat up the base material. Induction heating in induction brazing has proven an important tool in these joining processes. It allows for rapid localized heating, joining high-strength components with minimum loss of strength. An exact heat control in induction brazing allows the brazing process to be performed efficiently.Induction brazing alloys melt at high temperatures and provide high strength joints that can resist reasonably elevated temperatures without failure. Many of the alloys used for brazing are presented in the form of wire, strip, powder and also washers or rings for induction brazing process purposes.The design of the induction coil must be made to order to behavior of the metals and the dimension and shape of the joining parts. When using the induction brazing, special concern must also be given to the heating pattern; the method of pre-placing the joining alloy; the tolerances between mating parts; the thermal conductivity; and the expansion characteristics of the material to be joined.It is important that when designing brazing process (such in induction brazing) to consider the join strength which to have the maximum strength. This can be accomplished, in many instances, by pre-placing the joining alloy in such a way that it will flow into the joint by gravity and capillary attraction, showing uniform and complete penetration by appearance of the alloy at the opposite end of the joint.

Good fit and proper clearance

Clean base metals

Proper fixturing

Proper fluxing and atmosphere

Heating the assembly

Cleaning the brazed assembly

All these can be attained by following proper brazing procedure. To get step by step instructions about how to do brazing, read Basic Brazing Procedures To get the best quality and best cost effective brazing result is to have a best heating technique to ensure the best flow of filler metal in between the join of the material. In today demands the brazing process will also involve in a production line which a unique of brazing method is necessary to achieve best quality and cost effective. Therefore a unique induction brazing is widely using in such workIn induction brazing method temperature are usually reached in a matter of seconds for higher manufacturing productivity. The induction brazing method uses magnetism to induce electrical resistance to heat up the base material. Induction heating in induction brazing has proven an important tool in these joining processes. It allows for rapid localized heating, joining high-strength components with minimum loss of strength. An exact heat control in induction brazing allows the brazing process to be performed efficiently.Induction brazing alloys melt at high temperatures and provide high strength joints that can resist reasonably elevated temperatures without failure. Many of the alloys used for brazing are presented in the form of wire, strip, powder and also washers or rings for induction brazing process purposes.The design of the induction coil must be made to order to behavior of the metals and the dimension and shape of the joining parts. When using the induction brazing, special concern must also be given to the heating pattern; the method of pre-placing the joining alloy; the tolerances between mating parts; the thermal conductivity; and the expansion characteristics of the material to be joined.It is important that when designing brazing process (such in induction brazing) to consider the join strength which to have the maximum strength. This can be accomplished, in many instances, by pre-placing the joining alloy in such a way that it will flow into the joint by gravity and capillary attraction, showing uniform and complete penetration by appearance of the alloy at the opposite end of the joint.

how-induction-brazing-works

Good

Bad

Hot

Relationship between induction frequency and quenching depth (hardening depth)

waveform of DSP induction heaters

simulation of Faradays Law from University of Colorado Boulder

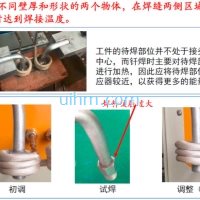

optimizing induction welding method for vehicle air conditioner

induction welding vehicle air conditioner vs common welding method

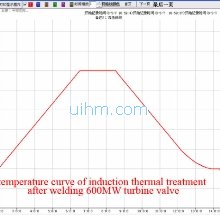

temperature curve of induction thermal treatment after welding 600MW turbine valve

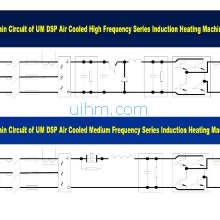

Main Circuit of UM DSP air cooled induction heaters

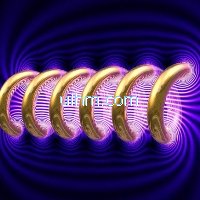

what is skin effect principle (magnetic force around induction coil)

Newest Comment

No Comment

Post Comment