Induction Bonding Steel Clips

Views Send Enquiry

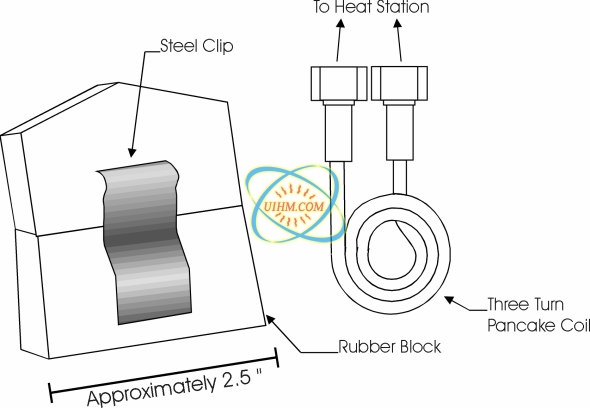

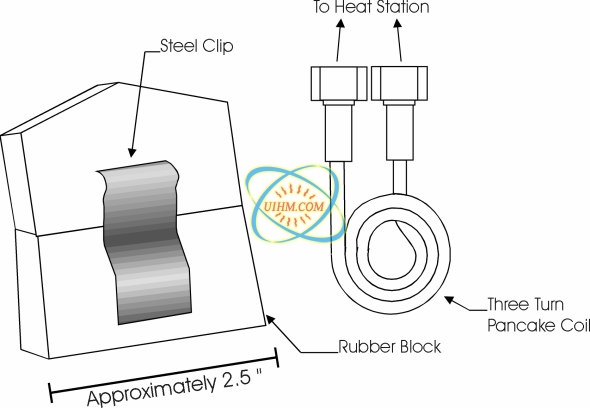

Objective To heat metal clips and press-bond them into rubber seals. The metal needs to be heated to 250°F to 350°F with a cycle time not exceeding 3 seconds

Material Steel clips and rubber sealer blocks

Temperature 250°F to 350°F

Frequency 373 kHz

Equipment Power of 6kW power supply including one remote heat station with one 1.2 μF capacitor using a specially

designed 3-turn pancake coil Process As illustrated below

Results Heating time of 1.5 seconds was attained; shorter heating times are possible due to fast response of the power supply. Bond formation is acceptable due to the even heat pattern produced through induction heating.

Material Steel clips and rubber sealer blocks

Temperature 250°F to 350°F

Frequency 373 kHz

Equipment Power of 6kW power supply including one remote heat station with one 1.2 μF capacitor using a specially

designed 3-turn pancake coil Process As illustrated below

Results Heating time of 1.5 seconds was attained; shorter heating times are possible due to fast response of the power supply. Bond formation is acceptable due to the even heat pattern produced through induction heating.

Good

Bad

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Newest Comment

No Comment

Post Comment