Simpley Heating by Induction

Views Send Enquiry

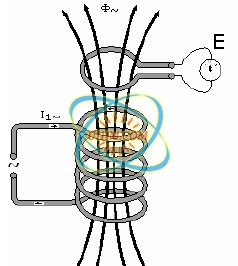

Electromagnetic induction, simply induction, is a heating technique for electrical conductive materials (metals). Induction heating is frequently applied in several thermal processes such as the melting and the heating of metals.

Heating by Induction has the important characteristic that the heat is generated in the material to be heated itself. Because of this, induction has a number of intrinsic trumps, such as a very quick response and a good efficiency. Induction heating also allows heating very locally. The heating speeds are extremely high because of the high power density.

General aspects

The inductor and the load behave as an inductive load and are compensated with capacitors. A

frequency converter feeds the entirety with a single-phase current at the desired frequency.

An induction installation also contains a cooling system (for frequency converter, inductor), a transport system and the necessary control and measuring apparatus.

3.2 Power supply and generators

The electrical supply can occur in different ways, depending on the frequency at which the installation has to work.

50Hz-installations:

The compensated load is directly connected to the transformer. The transformer can be regulated so that the current can be adjusted to the impedance of the load.

Hot

Relationship between induction frequency and quenching depth (hardening depth)

waveform of DSP induction heaters

simulation of Faradays Law from University of Colorado Boulder

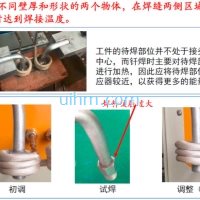

optimizing induction welding method for vehicle air conditioner

induction welding vehicle air conditioner vs common welding method

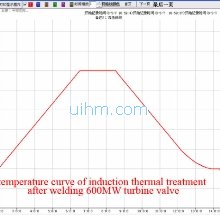

temperature curve of induction thermal treatment after welding 600MW turbine valve

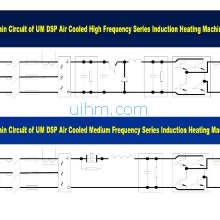

Main Circuit of UM DSP air cooled induction heaters

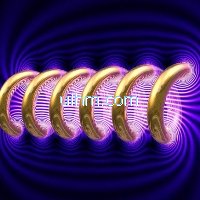

what is skin effect principle (magnetic force around induction coil)

Newest Comment

No Comment

Post Comment