Induction Heat Treating Type:

Induction Heat Treating Type:

Class: Induction Thermal TreatmentIntro: Induction heating has been used extensively for heat treating processes in a variety of metalworking applications.Some of these applications are associated with discrete parts such as shafts, bearings, gears, and hubs. Here, the most common processes are

Induction Forge steel rods Type:

Induction Forge steel rods Type:

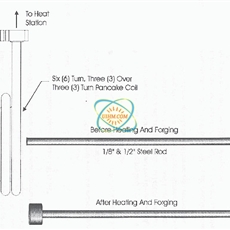

Class: MF Induction ForgingIntro: Objective To heat the ends of steel rods to 1800F prior to a forging operation. Processing of the rods includes heating, pressing in a two part die to forge the push rod end, and a final heating in a channel coil to temper the rods and relieve the forging

Induction Preheating Titanium Rods Type:

Induction Preheating Titanium Rods Type:

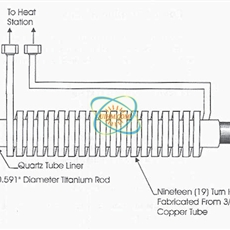

Class: Induction Tempering or PreheatingIntro: Objective To heat titanium rod blanks prior to forging into a turbine blade.Material Titanium rod blanks 0.591″(15.01mm) OD by 11.8″(299.7mm) longTemperature 2030F(1110C)Frequency 64 kHzEquipment • UM-HF-45kW induction heating system equipped with a rem…

Induction hardening belt retraction gear Type:

Induction hardening belt retraction gear Type:

Class: Induction HardeningIntro: Objective Heat the teeth of a soft steel seatbelt retraction gear to 1700F (926.7C) within two seconds for hardening.Material #4130 steel seatbelt retraction gears, water vortex quenching tank, electronically controlled air valves, adjustable timersTemper

Induction Hardening bed knife blade Type:

Induction Hardening bed knife blade Type:

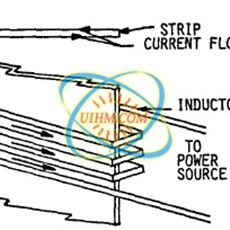

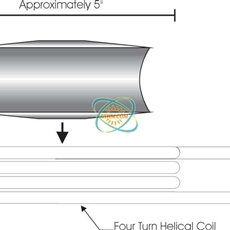

Class: Induction HardeningIntro: Objective Harden a selected area on an 18″(457.2mm) bed knife blade for a reel type lawn mower. The hardness desired is between 45 to 55 Rockwell C, and should be measured 0.062″(1.6mm) from the cutting edge.Material 1070 Steel Bed Knife Blade measuring …

Induction Hardening Surgical Knife Blades Type:

Induction Hardening Surgical Knife Blades Type:

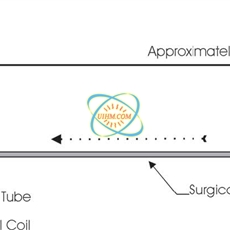

Class: Induction HardeningIntro: Objective Harden a 4″(101.6mm) section of a Stainless Steel surgical blade measuring 7″ (177.8mm) long. Hardness should be 48 to 53 Rockwell C on the blade after processing.Material 420 Stainless Steel Surgical Blades measuring 7″(177.8mm)long, 1/4″(6.…

Induction Hardening Pulleys Type:

Induction Hardening Pulleys Type:

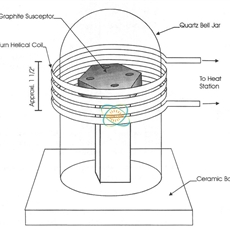

Class: Induction HardeningIntro: Objective Heat cast iron pulleys to 1600F(871.1C) in order to achieve a hardness of 55 Rockwell C.Material Ductile Iron Pulleys measuring 3 1/2″(88.9mm) OD and 2″ (50.8mm) high.Temperature 1600F (871.1C)Frequency 164 kHzEquipment • UM-UHF-10 kW inductio…

Induction Case Hardening Shaft Type:

Induction Case Hardening Shaft Type:

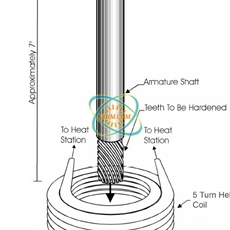

Class: Induction HardeningIntro: Case hardening shaftsObjective Harden the gear end of an armature shaft to 58-65 Rockwell C at a depth of 0.02″(.51mm) on the center line of the teeth and to 49-55 Rockwell C at a depth of .010″ (.3mm) on the center line of the root.Material Steel armatu…

Induction Hardening Steel Cam Type:

Induction Hardening Steel Cam Type:

Class: Induction HardeningIntro: Objective To harden the perimeter of ” thick steel cam assembliesMaterial ” thick steel cam assemblies of varying geometriesTemperature 1650 F (900 C)Frequency 177 kHzEquipment UM-UHF-20 kW, induction heating system, equipped with a remote heat station c…

Induction Hardening Steel Type:

Induction Hardening Steel Type:

Class: Induction HardeningIntro: Objective To harden various size ends of hand held marking stamps. The area to be hardened is 3/4” (19mm) up the shank.Material Steel stamps 1/4” (6.3mm), 3/8” (9.5mm), 1/2” (12.7mm) and 5/8” (15.8mm) squareTemperature 1550 F (843 C)Frequency 99 kHzEq…

Recommended

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel knife

induction deicing for aircraft carrier,naval vessels, naval craft, naval ships and boats, warship