-

Keywords"metal",total

32 records

-

induction cleve metal heat treat

Induction heating is often used in the heat treatment of metal items. The most common applications are induction hardening of steel parts, induction soldering/brazing as a means of joining metal components and induction annealing to selectively soften an a…

-

industrial furnace for metal melting 110kw steel copper gold silver [3]

![industrial furnace for metal melting 110kw steel copper gold silver [3]](/upfile/201303/30/small_Industrial-Furnace-for-Metal-Melting-110KW-Steel-Copper-Gold-Silver-3-34845105.jpg)

UIHM Medium Frequency Induction Heating Machines can be used for forging different kinds of metal material.Melting Capacity: 50G to 2000KG (by IGBT or SCR-Silicon Controlled Rectifier).Furnace: directly or tilting type.Industrial Furnace for Metal Melting …

-

large metal internal bore induction heat treatment

applications of (ultra) high frequency induction heating treatment Large metal internal bore induction heat treatment

-

6 meters metal track induction heat treatment

applications of (ultra) high frequency induction heat treatment 6 meters metal track induction heat treatment

-

6 meters metal track induction heating treatment

applications of (ultra) high frequency induction heat treatment 6 meters metal track induction heating treatment

-

induction heating for detaching metal from tyre

induction heating for detaching metal from tyre_1 induction heating for detaching metal from tyre induction heating for detaching metal from tyre

-

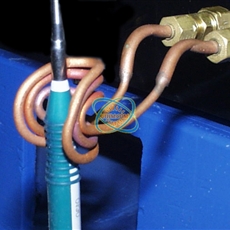

parallel shape induction coil heating metal

Parallel shape induction coil heating metal2 Parallel shape induction coil heating metal-1 Parallel shape induction coil heating metal Base Induction Coil Design and Theory Induction Coil Design and Fabrication

-

metal to plastic by induction bonding

Objective To heat a steel magnetic steel post to 300F for a bonding application.Material Magnetic steel posts Plastic handleTemperature indicating paintTemperature 300F (149C)Frequency 288 kHzEquipment Power of 6 kW, 100-400 kHz induction heating power sup…

-

induction annealing metal stamp sets

Objective Heat the opposite end of a metal stamp so that it mushrooms instead of cracks/splits when struck by a hammer.Material S-7 steel of varying rectangular cross sectional sizesTemperature 1400-1800 F (760-982) CFrequency 204-165 kHzEquipment 25 kW, i…

-

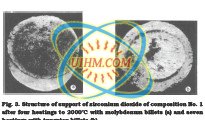

melt refractory metals with induction heating

In the Ail-Union Scientific-Research Tube Institutes industrial induction electric furnaces heated to 2000-2300C, cylindrical billets of high-melting alloys are placed on refractory supports. To select materials for the supports which do not react with mol…