-

Keywords"coating",total

7 records

-

remove plastic coating from steel tubes by induction heating

Objective Recover the polypropylene insulation from hollow steel tubes to allow recycling of both the tubes and the insulation. Material Hollow steel tubes 1/8” (0.318 cm) to 5/8” (1.59 cm) IDProtective polypropylene coating Temperature 150 C (302F…

-

induction vacuum coating with multi um-dsp induction heater

induction vacuum coating with multi UM-DSP induction heater

-

induction coating by air cooled clamp induction coil

induction coating by air cooled clamp induction coilcustom desigh air-cooled clamp coilclamp induction coil with foot switch

-

ultra-high frequency(uhf) induction vacuum coating for solar collector tube

ultra-high frequency(UHF) induction vacuum coating for solar collector tubesinduction vacuum coating for solar collector tubeultra-high frequency(UHF) induction vacuum coating for solar collector tubeinduction heating solar collector tube

-

high frequency induction evaporation coating and painting silica-plated

Our UM-60AB-HF high frequency induction heating machine can be used for induction evaporation coating and induction painting Silica-plated, it will bring a quicker speed and safe work environment.High frequency induction evaporation coating(IGBT-50KW-30KHz…

-

induction curing coating

Objective Curing a coating on both sides of an aluminum piston at a rate of 1” (25.4mm) per secondMaterial 4 aluminum pistons weighing 1lb (.45kg) each, 3.75” (95.25mm) dia and 2.5” (63.5mm) highTemperature 225 F (107.2 C)Frequency 6 kHzEquipment • Pow…

-

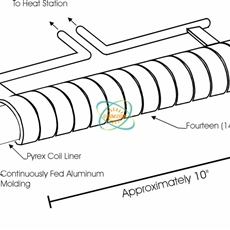

induction coating aluminum

Objective To heat an aluminum molding shape in order to activate an adhesive coating prior to applying the vinyl Material Aluminum molding folded from a flat sheet measuring 2″ wide and 0.03″ thick. The final form measures 5/8″ by 1″ Temperature 500F…