Induction curing coating

Views Send Enquiry

Objective Curing a coating on both sides of an aluminum piston at a rate of 1” (25.4mm) per second

Material 4 aluminum pistons weighing 1lb (.45kg) each, 3.75” (95.25mm) dia and 2.5” (63.5mm) high

Temperature 225 ºF (107.2 ºC)

Frequency 6 kHz

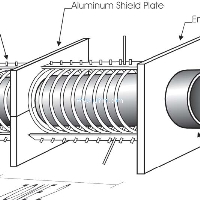

Equipment • Power of 70 kW induction heating system, equipped with a remote workhead containing three 26.8μF capacitors for a total of 80μF

• An induction heating coil designed and developed specifically for this application.

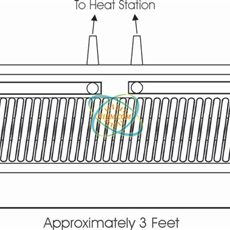

Process A three turn channel coil 19” (48.26cm) long is used to anneal 4 pistons running though the coil with a distance of 6” (15.24cm) between centers. The parts run at a rate of 1” (25.4mm) per second and the 4 parts reach 225 ºF (107.2 ºC)

and are annealed in 40 seconds.

Results/Benefits Induction heating provides:

• Hands-free heating that involves no operator skill for manufacturing

• Ideal for in-line production processes because of its ability to produce repeatable, rapid and accurate heating cycles

• Improved thoughput

curing-coating

Related Content

ultra-high frequency(UHF) induction vacuum coating for solar collector tube

Induction Curing Adhesive for Steel Motor Shaft

High frequency induction evaporation coating and painting Silica-plated

Induction Curing epoxy

Induction Curing adhesive

Induction Curing Ceramic Fiber

Induction Curing Measuring Tape Paint

induction coating by air cooled clamp induction coil

Hot

induction painting after induction bending for pipelines

induction heating steel plate

induction remove copper from aluminium

induction heating stator frame

induction heating graphite mould

difference between induction heating inner surface and outside surface of steel ring

induction heating steel pot bottom

induction heating for heat preservation

Newest Comment

No Comment

Post Comment