-

Keywords"curing",total

6 records

-

induction curing adhesive for steel motor shaft

Objective: induction Curing Adhesive for the internal wall (inner interface) of a steel motor shaft to bond electronic stress/strain gauges into place.Material: Steel shaft measuring 6.65" (168.9mm) OD, 5.5"(139.7mm) ID and 70" (1.8m) long. …

-

induction curing epoxy

Objective Heat the end of an aluminum copier roller to 400 F (200 C) to cure epoxyMaterial Aluminum roller 4.75” (120mm) diameter, 2’ (0.6m) long with 1.5” (38.1mm) thick plug at endTemperature 400 F (200 C)Frequency 52 kHzEquipment • Power of 25 kW in…

-

induction curing coating

Objective Curing a coating on both sides of an aluminum piston at a rate of 1” (25.4mm) per secondMaterial 4 aluminum pistons weighing 1lb (.45kg) each, 3.75” (95.25mm) dia and 2.5” (63.5mm) highTemperature 225 F (107.2 C)Frequency 6 kHzEquipment • Pow…

-

induction curing adhesive

Objective To Cure adhesive in aluminum filter endsMaterial Aluminum filter, steel end caps & plastisol adhesiveTemperature 200 FFrequency 277 kHzEquipment Power of 6kW induction heating system, equipped with a remote workhead containing two 0.1uF capa…

-

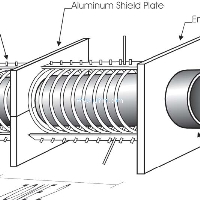

induction curing ceramic fiber

Objective To heat-cure a NextelTM Ceramic fiberMaterial Ceramic fiber 30,000 (9,145) ft(m) Steel tubeTemperature indicating paintTemperature 1300(700) F(C)Frequency 70 kHzEquipment Power of 45kW, 50-450 kHz solid-state induction power supply with a remote …

-

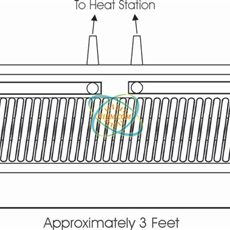

induction curing measuring tape paint

Objective To heat measuring tape stock at a maximum rate of 600 feet per minute to cure the applied paint. The heating coil is to accommodate the 3/8″ wide stock within the customer’s current framework. Curing must occur above 400F at the rate specified.…