Induction Curing Measuring Tape Paint

Views Send Enquiry

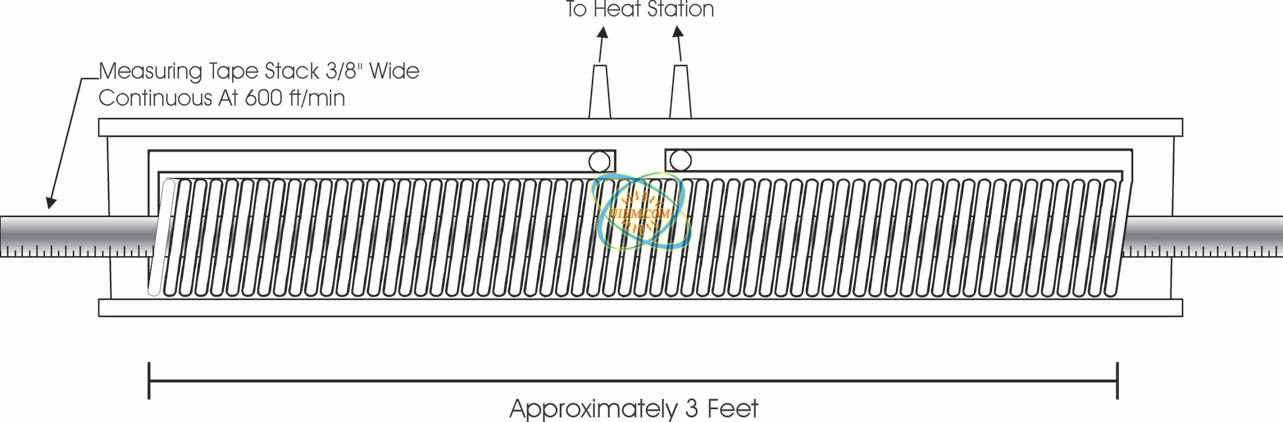

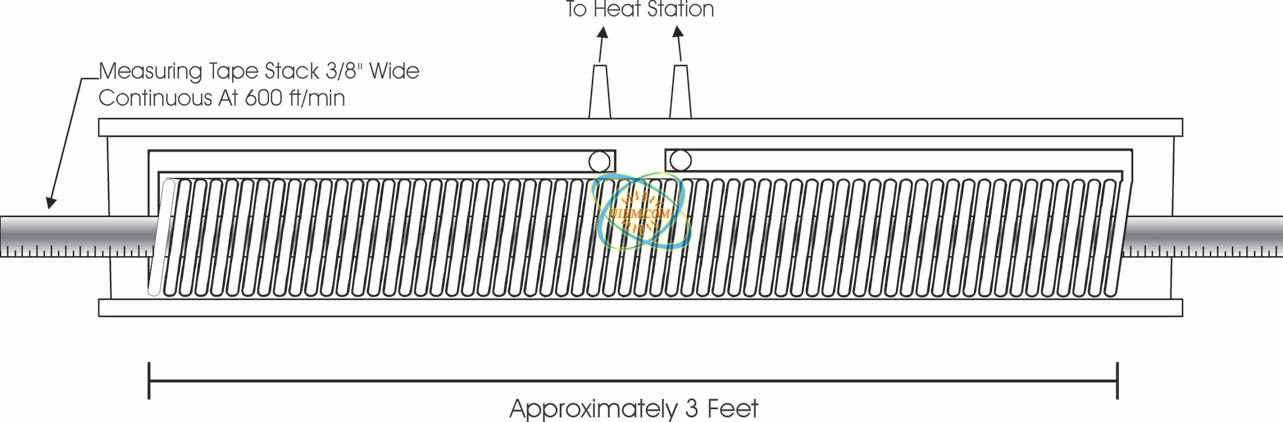

Objective To heat measuring tape stock at a maximum rate of 600 feet per minute to cure the applied paint. The heating coil is to accommodate the 3/8″ wide stock within the customer’s current framework. Curing must occur above 400°F at the rate specified.

Material Steel Measuring Tape stock, 3/8″ wide on a continuous feed.

Temperature Above 400°F

Frequency 75 kHz

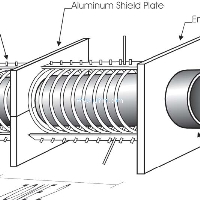

Equipment Power of 45kW output solid state induction power supply with remote heat station housing eight (8) 0.33 μF capacitors totaling 0.66 μF, along with a 30″ multi turn helical coil designed specifically for this application.

Process The UIHM 20kW output solid state induction power supply along with a unique 30″ long multi turn helical coil was found to produce the following results.

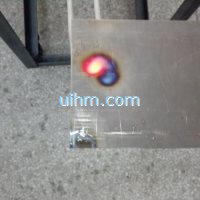

Results • A temperature of 500°F was achieved, at the necessary rate, using the unique 30″ multi-turn helical coil which surpasses the customer’s requirement of 400°F.

• The helical coil was designed to integrate with the customer’s present framework to eliminate any re-fixturing.

• The helical coil allows for the tape to travel internally with absolutely no contact thus maximizing surface quality.

Material Steel Measuring Tape stock, 3/8″ wide on a continuous feed.

Temperature Above 400°F

Frequency 75 kHz

Equipment Power of 45kW output solid state induction power supply with remote heat station housing eight (8) 0.33 μF capacitors totaling 0.66 μF, along with a 30″ multi turn helical coil designed specifically for this application.

Process The UIHM 20kW output solid state induction power supply along with a unique 30″ long multi turn helical coil was found to produce the following results.

Results • A temperature of 500°F was achieved, at the necessary rate, using the unique 30″ multi-turn helical coil which surpasses the customer’s requirement of 400°F.

• The helical coil was designed to integrate with the customer’s present framework to eliminate any re-fixturing.

• The helical coil allows for the tape to travel internally with absolutely no contact thus maximizing surface quality.

Next: Induction Curing Ceramic FiberPrevious: Induction Bonding Solar Panels

Good

Bad

Related Content

induction painting after induction bending for pipelines

Induction Curing Adhesive for Steel Motor Shaft

High frequency induction evaporation coating and painting Silica-plated

Induction Curing epoxy

Induction curing coating

Induction Curing adhesive

Induction Curing Ceramic Fiber

induction painting steel pipes online

Hot

induction tempering SS-Steel pot

induction tempering copper plate

induction tempering copper plate

induction tempering WT3mm steel pipes

induction tempering titanium plate with moving handheld induction coil

induction tempering steel wire online by multi induction heaters

induction tempering steel plates

induction tempering steel plate

Newest Comment

No Comment

Post Comment