- HF Induction Brazing

- ┣━━ HF Induction Brass Solder

- MF Induction Forging

- Induction Hardening

- HF Induction Quenching

- HF Induction Annealing

- Induction Tempering or Preheating

- Induction Melting

- ┣━━ Rare Metals Melting

- ┣━━ High Capacity Melting

- Induction Shrink Fitting

- Induction Thermal Treatment

- Induction Heating for Aerospace

- Induction Bonding

- Induction Soldering

- Induction Welding

- Induction Jointing

- Other Induction Applications

-

Induction Annealing copper tubing

Objective To heat both ends of a copper tube to anneal as soft as possible 1.5” (38.1mm) from end and retain full hardness next to annealMaterial 1.625” (41.275mm) dia x 24” (609.6mm) long copper tubeTemperature 1500 F (815.5 C)Frequency 70 kHzEquipment…

2006/10/02

-

Induction Annealing Brass crimping

Objective To anneal a small area of an electrical contact for crimpingMaterial Brass female spade electrical contact with single transverse loop at end 0.5h(12.7mm) long, 0.25h(6.3mm) wide and 0.03h (0.8mm) thick, 1000oF (538oC)heat paintTemperature …

2006/10/02

-

Induction Annealing steel shaft

Objective Heating a steel rod to 1200F (649C) for an annealing, stress relief applicationMaterial 1.062” (26.97mm) dia type T-410 stainless steel bar 6’ (1.82m) long & 1.25” (31.75mm) dia T-416 stainless steel bar 6’ (1.82m) longTemperature 1200F (…

2006/10/02

-

Induction Annealing locknuts

Objective To heat locknuts to 2150F (1176C) for annealingMaterial Waspaloy locknutTemperature 2150F (1176C)Frequency 382 kHzEquipment • UM-10AB-UHF induction heating system, equipped with a remote workhead containing one 0.66μF capacitor.• An induction …

2006/10/02

-

Induction Annealing metal stamp sets

Objective Heat the opposite end of a metal stamp so that it mushrooms instead of cracks/splits when struck by a hammer.Material S-7 steel of varying rectangular cross sectional sizesTemperature 1400-1800 F (760-982) CFrequency 204-165 kHzEquipment 25 kW,

2006/10/02

-

Induction Annealing Saw blades

Objective Anneal saw blades used for cutting bread, prior to hole punching.Material .38” (9.6mm) wide and .51” (12.9mm) wide continuous strips of 400 series stainless steel.Temperature 600C (315.6F) for one secondFrequency 229kHzEquipment • UM 6 kW …

2006/10/02

-

Induction Annealing Tungsten Rods

Objective To heat customer-supplied rods of various diameters (0.14 inch to 0.49 inch) to 4170F (2300C) at 2-4 feet per minuteMaterial Tungsten and Molybdenum; Tests are run in an atmosphere of Nitrogen or Hydrogen avoid oxidation of the materials.Tempera

2006/10/02

-

Induction Annealing Titanium fasteners

Objective Heating a titanium fastener to 1100-1450F (593-788C) for an annealing process.Material 0.06” (1.5mm) high zone on a titanium fastener measuring 0.163-0.375” (4.14-9.52mm) in diameter and 0.5-3.0” (12.7-76.2mm) in lengthTemperature 1100-1450F (…

2006/10/02

-

Induction Annealing Brazing Wire

Objective: Anneal a brazing wire for preform production.Material :Copper Nickel Silver 2774 Alloy rod 0.070″ (1.8mm) diameter.Temperature 650F(343.3C)Frequency 281 kHzEquipment • UM-06A-UHF induction heating system equipped with a remote workhead with on…

2006/10/02

-

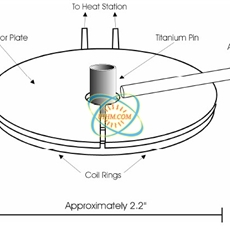

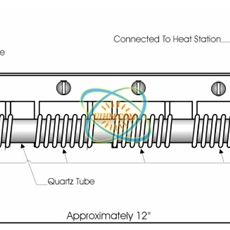

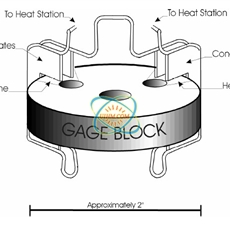

Induction Annealing Thread Ring

Objective:To selectively and uniformly anneal two sections of a thread ring gage block from the hole to the outside surface from a hardness of Rc 59-61 to Rc 45. The gage blocks are made from O6 steel and range in size from 1″ to 8 1/2″ in diameter and r…

2006/10/02

© Copyright 2025. uihm.com All Rights Reserved.