-

Keywords"or",total 1005 records

-

theory and examples of ac resonant charging,

RESONANT CHARGING The connection of a Tank capacitor across an inductively ballasted supply creates a resonant circuit. The resonant frequency of this arrangement is determined by the valu…

Date:2009/10/01

-

induction heating motor

Heating motor Objective Heat steel to help bond an injection molded piece and help the reflow.Material Steel motor body, 60 x 60 x 27 (2.4 x 2.4 x 1.1) mm(in)Temperature 260C (500F)Frequency 237 kHzEquipment • Power of 20kW induction heating system, equip…

Date:2008/08/03

-

induction heat seat springs for powder coat

Heat seat springs for powder coat Objective Heat the steel spring assemblies of automotive seats to powder coatMaterial Steel wire springs ~24” (61 cm) long, 1/8 “ (3.175mm) diameter cross sectionTemperature 500 F (250 C)Frequency 57 kHzEquipment Power …

Date:2008/08/03

-

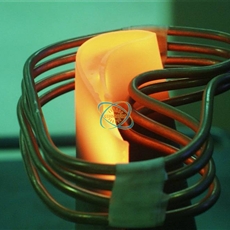

induction hot forging

Hot Forging Forging can be defined as a manufacturing process, which involves heating and pressing a metal at a high temperature into stronger parts. Hammers, presses and upsetters are the equipments used in the forging process. Some of the metals that can…

Date:2008/08/03

-

induction heating aluminium susceptor

Heating aluminium susceptor Objective Expand powder into solid form for use in crash helmetsMaterial Microspheric powderAluminium chamber 110mm (4.3 in.) diameter x 35mm (1.3 in.) deep used to hold powderTemperature 150 oC (302 oF)Frequency 54.5 kHzProcess…

Date:2008/08/03

-

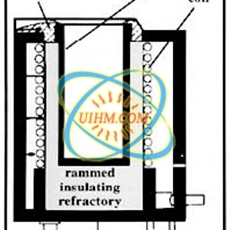

crucibles for induction melting

Crucibles for Induction MeltingThe proper crucible for melting of ferrous alloys is often viewed as a insignificant decision when, in reality, considerable effort should be given to this important decision. Crucible performance can have dramatic effects on…

Date:2008/02/03

-

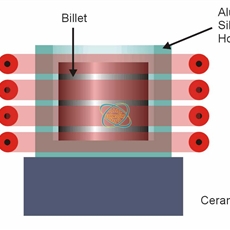

induction forging inconel billets

Forging Inconel Billets Objective To heat inconel billets to 2050F (1121.1C) for a forging process.Material Small inconel billets 0.39” OD, 0.7” length (.99mm OD, 17.8mm length) with ceramic crucible 1.0” OD, 0.7” ID, 1.4” length (25.4mm OD, 17.8mm ID…

Date:2008/02/03

-

how induction brazing works

How Induction Brazing Works Induction brazing is a process where two or more materials such as pipe are joined together with a molten space filler metal using an induction heating coil which delivers a very high temperature. The induction brazing process w…

Date:2008/02/03

-

induction heating fan blades for welding

Heating fan blades for welding Objective To uniformly heat jet engine turbine fan blades to 1800F (982.2C) within five minutes for a welding applicationMaterial Jet engine turbine fan blades with 2”(50.8mm) length tipTemperature 1800F (982.2C)Frequency 21…

Date:2008/02/03

-

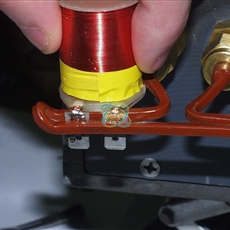

induction soldering wires onto connector

Soldering wires onto connector Objective Heat connector assemblies for solderingMaterial Device assemblyTin plated brass terminals Solder pasteTemperature 500F (260C) 5-7 secondsFrequency 360 kHzEquipment Power of 6 kW induction heating system equipped wit…

Date:2008/02/03

© Copyright 2025. uihm.com All Rights Reserved.