Heat Treatment Class: Induction Heat Treatment

Heat Treatment Class: Induction Heat Treatment Intro: In recent years this plant is using hardening with preceding induction heating for morethan 50% of the total amount of heat-treated parts. These are mainly tractor parts made from45, 40Kh, 38KhGS, and 33KhS steels. The overwhelming majority of parts (85%

Heat Treating Forgings Class: MF Induction Forging

Heat Treating Forgings Class: MF Induction Forging Intro: Forgings are subjected to final heat treatment or intermediate heat treatment to improve the maohinabitity.The processes that occur during heat treatment of forgings can be divided into two groups — processesoccurring at temperatures above and below Ac 3.

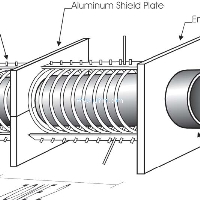

Induction Heating Technology in aerospace Class: Induction Heating for Aerospace

Induction Heating Technology in aerospace Class: Induction Heating for Aerospace Intro: The purpose of this Tech Note is to demonstrate the advantages of Induction Heating technology like new Nova Star technology for precision induction heating applications. In each section, we will show how a particular aspect of this new technology makes a

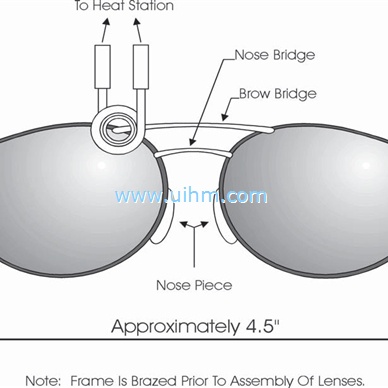

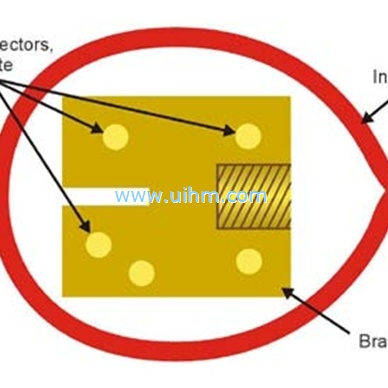

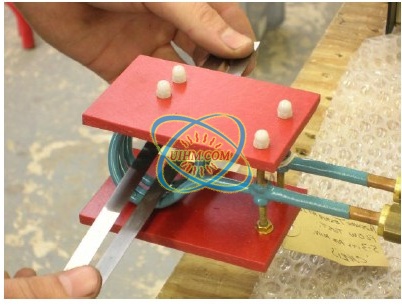

Induction Soldering Steel to Brass Class: HF Induction Brass Solder

Induction Soldering Steel to Brass Class: HF Induction Brass Solder Intro: ObjectiveHeat an assembly of small, gold-plated steel connectors to a brass block.Approx. 1/8” (3.2mm) diameter gold-plated steel connectors,1”(25.4mm) square x 1/4” thick brass block ,600F(315.6C),240 kHzTemperature,Frequency,Equipment6 kW induction he…

Induction Annealing Stainless Steel Class: HF Induction Annealing

Induction Annealing Stainless Steel Class: HF Induction Annealing Intro: Induction Annealing stainless steel bread cutting saw bladesObjective: Anneal saw blades used for cutting bread, prior to hole punching.Material :.38” (9.6mm) wide and .51” (12.9mm) wide continuous strips of 400 series stainless steel.Temperature :600C (…

Induction Shrink Fitting Class: Induction Shrink Fitting

Induction Shrink Fitting Class: Induction Shrink Fitting Intro: Induction shrink fitting refers to the use of induction heater technology to pre-heat metal components between 150 C (302 F) and 300 C (572 F) thereby causing them to expand and allow for the insertion or removal of another component.Typically the lower t

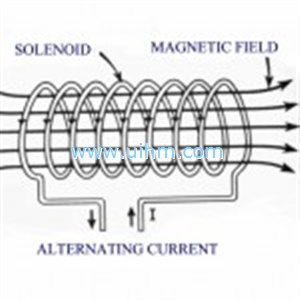

Induction surface hardening Class: Induction Hardening

Induction surface hardening Class: Induction Hardening Intro: Induction Surface HardeningKelvin Effect, Mean Curvatures and Load Impedance in Surface Induction Hardening: AnAnalytical Approach including Magnetic LossesAbstract– Kelvin effect (Skin effect) is used in surface hardening produced by induction heating of

Induction Brazing Copper Contacts Class: HF Induction Brass Solder

Induction Brazing Copper Contacts Class: HF Induction Brass Solder Intro: Objective Heat silver contacts and brass/copper bus for brazing applicationMaterial Silver contact .75 (19mm) diameter, brass and copper bus 2” x 1” (50.8 x 25.4mm), braze shims, white fluxTemperature 1300 F (704 C)Frequency 320 kHzEquipment • UM-UHF-10…

Induction Brazing carbide tip Class: HF Induction Brazing

Induction Brazing carbide tip Class: HF Induction Brazing Intro: Objective Braze a carbide tip to a 4140 steel cutting toolMaterial Carbide Isograde C2 & C5 tips, 4140 circular steel cutter, flux and silver braze shimTemperature 1400 F (760 C)Frequency 290 kHzEquipment • UM-UHF-20kW induction heating system, equipp

Induction Brazing two positions on a stainless steel manifold Class: HF Induction Brazing

Induction Brazing two positions on a stainless steel manifold Class: HF Induction Brazing Intro: Objective Simultaneously braze two positions on a stainless steel manifoldMaterial Stainless steel manifold 4” (101.6mm) long, 1” (25.4mm) in diameter and nico brazeTemperature 1800 F (982 C)Frequency 198 kHzEquipment • UM-UHF-20kW induction heating sys…

Recommended

induction brazing diamond segment

induction shrink fitting for Automotive cylinder rod

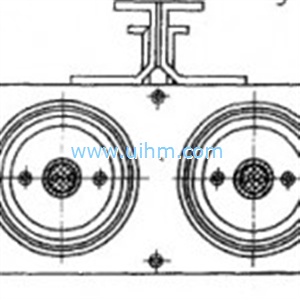

induction heating drill pipe by twin coils

Ball stud high-frequency induction hardening

Splined shaft induction hardening

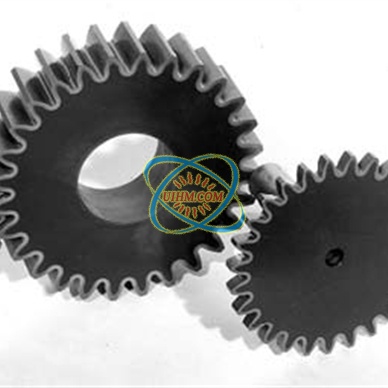

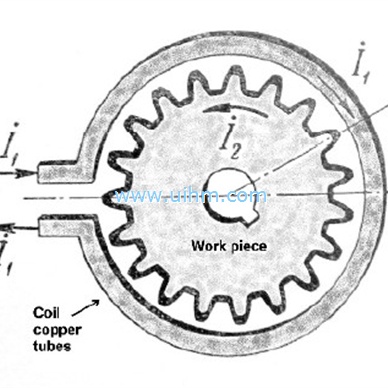

Sprocket induction hardening

Gear shaft induction hardening

High frequency induction brazing welding steel bar