How to choose induction heaters

Views Send Enquiry

Induction heating by high frequency Induction heaters output current through the coil generates an alternating magnetic field, through the induction loop on the formation of eddy currents in the metal workpiece, so that the rapid heating, and induction loop itself does not produce heat, has been for decades history. The mid-1990s, solid-state IGBT module as the core began to induction heating equipment, and tube high-frequency induction heating equipment, devices and silicon compared to saving 10% -40%. Once available, on its energy-saving environmental protection, processing of high quality, easy operation, safe and reliable operation, maintenance costs, and many other advantages become the best field of small metal heating heating.

Different frequency induction heater, resulting in different heating effect, determines the heating quality is good or bad;-power size, determines the speed of the workpiece and the processing efficiency of the heating, so the workpiece according to heating requirements, select the correct frequency and power is very important.

First, how to choose the frequency

Induction heating equipment, according to the different output frequencies can be divided into: UHF, HF, VHF, MF and so on. Heating process required different needs at different frequencies, if you choose the wrong frequency can not meet the heating requirements, such as slow heating time, low efficiency, uneven heating, the temperature below standard, likely to cause damage to the workpiece.

Correct choice of frequency, first, to understand the product requirements of the heating process, probably said to have the following situations:

1, the workpiece through the heat, such as: fasteners, standard parts, auto parts, hardware tools, rigging, and other hot-rolled twist drill of hot forging, the workpiece diameter, the greater the frequency should be lower. Such as:

Φ4 mm below apply, UHF (100-500KHz)

Φ4-16, mm applies high frequency (50-100 KHz)

Φ16-40 mm applied over the audio (10-50 KHz)

Φ40 mm above the applicable MF(0.5-10 KHz)

2, heat treatment, shafts, gears, hardened and annealed stainless steel products and so on, to quench, for example, hardened layer of the workpiece requires more light, the frequency should be higher, deeper hardened layer, the frequency should be lower. Such as:

02.-0.8mm hardened layer is applied 100-250 KHz UHF, HF

1.0-1.5mm apply to 40-50 KHz high-frequency, ultrasonic,

1.5-2.0mm audio application 20-25 KHz ultra-

2.0-3.0mm ultra-apply 8-20 KHz audio, MF

3.0-5.0mm apply 4-8 KHz MF

5.0-8.0mm apply 2.5-4 KHz MF

3, brazing, soldering head, lathe, reamer, milling cutter, drill, etc., and stainless steel pot of different materials, hybrid welding, soldering the larger volume, more frequency should be reduced,

Welding, for example by turning tool, such as:

20 mm the following tools for 50-100 KHz frequency

20 – 30mm above the tool apply to 10-50 KHz high-frequency, ultrasonic,

30 mm above the tool, apply 1-8 KHz MF.

4, melting gold, silver, copper, lead and precious metals

According to the specific production efficiency furnace and determined. Optional high-frequency small-capacity, most of the election super audio, MF

Super audio applications to meet the casting industry in general, 200KG melting aluminum ingots per hour of general application.

Second, how to choose the power

When the workpiece according to your requirements, determine the frequency of the machine, the next step is to choose the appropriate production according to the power of the machine. The greater the power the machine, the faster the heating, but the price will increase, low-power devices, low cost, the heating is slow.

1, the induction heating rate of reactive power are usually two: output power and oscillation power.

AC induction heating equipment must be rectified, get current and voltage oscillation, the oscillation power is the product of the two.

Commonly referred to as power, are the machine’s load power, also known as power output, actual output power of the oscillation power is only about 60%. Calibration equipment such as oscillation and output power 50KW 30KW power induction heating equipment and then heated under the same conditions the same effect.

The following is a commonly used device output power / power oscillation contrast.

25KW/42 KW, 30 KW / 50 KW, 50KW / 80 KW, 80 KW / 125 KW

Currently, induction heating equipment is not state of the model calibration method, like most manufacturers mark their products into the make identification number + power forms such as: XX-20, YY-60, ZZ-100, etc., so some manufacturers usually will power the nominal oscillation power, and some manufacturers will calibrate the oscillator power output or just say generally labeled as the power to mislead customers. What is more, simply do not write power, the input current number of calibration models to allow customers to mistakenly think that literacy is the machine behind the power. A far cry from the two actually. The induction heating equipment, usually after a long time to buy will not be updated, so customers understand the difference between the two in the area are often rude awakening.

So, when the company introduced the product to you, do not care only about models, do not forget to ask how much of his output, done a pretty good idea.

2, processing the same piece, working at different speeds, power is very different choices

For example; a fastener to hot forging process Φ30 mm length 50mm screw, the heating temperature of 1,000 degrees, the production rate of 20 / minutes, it should choose a frequency for ultra-audio (10-40KHZ) output power 80KW machine use, if the production rate reduced to 10 / minute, a super-audio frequency (10-40) output power of the machine will be able to meet the application 50KW, 80KW 50KW higher than the price, so the manufacturers according to their actual situation, select the most appropriate model, to avoid wastage.

In addition, the power of choice must take into account fluctuations in electrical voltage, for users who use the three-phase AC voltage to reduce 10V, the output will be reduced about 7%, in general, companies use the device , a group of workpiece heating time is fixed, when the voltage is lowered, in order to guarantee the achievement of the heating effect, it should turn up the machine power, to achieve the same heating effect. However, if your device maximum power heating time is the premise of the state set, when the voltage decreases, the only method by extending the heating time to achieve the same heating effect, so we must re-test, get the time to set parameters, delay production , we can not guarantee the quality of the workpiece. It is proposed that in use, the device power output adjusted to about 85-90% power state, leaving little margin, so that can prolong life, they can easily deal with the negative image caused by voltage fluctuations

Hot

Relationship between induction frequency and quenching depth (hardening depth)

waveform of DSP induction heaters

simulation of Faradays Law from University of Colorado Boulder

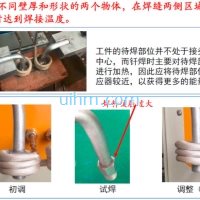

optimizing induction welding method for vehicle air conditioner

induction welding vehicle air conditioner vs common welding method

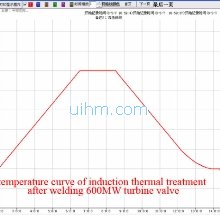

temperature curve of induction thermal treatment after welding 600MW turbine valve

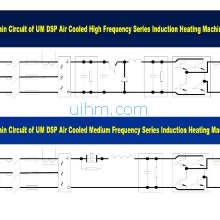

Main Circuit of UM DSP air cooled induction heaters

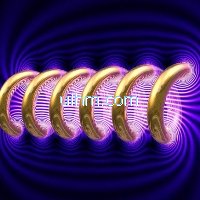

what is skin effect principle (magnetic force around induction coil)

Newest Comment

No Comment

Post Comment