IGBT Induction Heater Profiles

Views Send Enquiry

MF IGBT power transistor module is in the early 1990s, foreign advanced technology, developed a new type of variable frequency induction heating equipment, won the “National New Product Award”. Wide range of applied high-capacity, high efficiency melting occasion, and through high-frequency Induction heated machine, heat treatment and other heating applications.

IGBT induction heating power supply, as a constant power output of power supply, Inverter part series resonance, using advanced IGBT transistor devices. The new power supply in many ways superior to the performance of SCR frequency power supply, is the old type KGPS-Series SCR frequency furnace replacements. Mainly used in smelting ordinary carbon steel, stainless steel, can be used for smelting copper, aluminum and other nonferrous metals, can also be used to melt silicon, polysilicon and other non-metallic. With high efficiency, rapid melting of the advantages of burning metal element less, less slag, liquid steel quality is good. Improve the casting quality, and yield, reduce production costs.

Second, the product advantages:

1, IGBT frequency power supply as a constant power output of power, some for the use of series resonant inverter and inverter voltage is high, all the IGBT IF frequency energy than the average SCR; IGBT transfer power FM frequency used, some with full-bridge rectifier rectifier, inductor and capacitor filter, and has been working on 500V, so the frequency IGBT high harmonic generation of small, low industrial pollution on the grid.

2, energy-efficient IGBT power than traditional silicon transistor IF frequency power supply can be 15% -25% energy saving, energy saving under the main reasons are the following aspects:

1) high voltage inverter, current, circuit loss, this section can be about 15% energy saving, energy-efficient IGBT power transistor inverter voltage frequency 2800V, while the traditional SCR frequency power inverter voltage is only 750V, current small nearly four times, the line loss greatly reduced.

2) high power factor, power factor is always greater than 0.98, no power loss, this part of the SCR frequency power saving than 3% -5%. As the energy-frequency IGBT transistors with a half-controlled rectifier power supply means, rectifier thyristor conduction angle is not adjusted, so the whole work process is always greater than 0.98 power factor, no power loss. .

3, high-order harmonic interference: energy-efficient IGBT power transistor frequency semi-controlled rectifier three-phase full-wave rectifier rectifier mode, the phase sequence is not required, the DC voltage is always at the highest, do not adjust the conduction angle, so it does not will produce higher harmonics, does not affect the substation reactive power compensation capacitor run, does not pollute the power grid, transformers, switch does not heat, will not interfere with other electronic equipment within the factory running.

4, constant power output: SCR frequency power supply using regulator power adjustment, while the energy-using IGBT power transistor FM frequency transfer function, it is not how much charge and thickness of the lining in the melting process to maintain constant power output.

5, equipment reliability, maintenance costs low. In the series circuit and the inverter must switch to bear the full flow through the furnace coil current. In general, the current is parallel-type power inverter circuit by switching the total current of 10 to 20 times. Because the nature silicon defects exist, making one but not at any time after the turn off, so in case of failure to protect the SCR is a very difficult thing, but IGBT can be detected in case of failure to signal the moment you can shut off, thus the power to give good protection. IGBT transistors receive the trigger signal will be maintained during the turn, trigger signal will disappear at any time off IGBT. IGBT can be a hundred millionth of a second off, so far more than the same type of SCR inverter 100 times faster. Troubled years of the user’s main problem is the failure rate is too high SCR. Large maintenance costs and serious impact on production. The IGBT power transistors on the security to overcome this fatal weakness.

To sum up: the biggest advantages of this new power is to save energy, intermediate frequency smelting a ton of steel is generally SCR 900 degrees around, and IGBT transistors IF melting one ton of steel about 630 degrees. And the melting speed, 0.5 tons of steel melting water only 50 minutes. Increase production, reduce the burning of various components, especially the melting of special castings. It enables users to get the best value for money.

Three, IGBT induction heating power supply of the advantages and disadvantages compared with KGPS:

1, energy: the energy consumption of SCR IF it 900 degrees in 850 / ton, while the frequency of the power transistor at 630 degrees (0.5 tons of equipment power consumption at 630 degrees; one ton equipment energy consumption 600 degrees). SCR frequency than saving about 28%. Annual production by 1000 tons of steel per year of water saving calculated 14 million. Calculated as follows:

Saving 200 kWh per tonne basis, production of 1,000 tons of steel water power for the savings: 1000 tons × 200 ° / t = 200000 degrees 0.7 yuan per kWh calculated electricity production of 1,000 tons for the electricity savings can be achieved: 200000 ° × 0.7 yuan / kWh = 140,000 yuan

2, the melting rate: the case of the same power, for example: 0.5 tons of equipment, 300KW power in the melt water, 0.5 tons of steel, silicon device requires 100 minutes to 60 minutes or so IF IGBT present SCR equipment in order to shorten melting time, the factory in order to meet the requirements of users, to production, to speed, the use of induction loop will reduce the number of turns, increasing the supply power, increasing transformer capacity and other means, typically using 450 ~ 500KW power supply, power supply so that it IF more than the IGBT with a 150 ~ 200KW. That is just a 315KVA transformer frequency IGBT’s on it, while the SCR equipment starting a 450 ~ 500KVA transformer power supply. Transformer base electricity charge per KVA per month $ 20 per month to pay more 150KVA × 20 = 3000 yuan / month, pay the electric bill 3000 yuan per year × 12 months = 30 006 thousand dollars.

3, high harmonics: SCR equipment generates a lot of high frequency harmonics, which resulted in the consequences of pollution to the power grid sine wave distortion, transformer Induction heating unit, heat switch, electronic devices interfere with the operation of the factory, the factory reactive power compensation capacitors can not be run while the IGBT device produces high frequency harmonics, which would not have these adverse effects.

4, the failure rate:

1) SCR IF furnace failure rate is high, inverter side of the SCR is often the breakdown, the capacitor requires regular replacement, often burning reactor coil, a device materials direct losses every year several thousand dollars, the other In the repair process, the molten steel cooling solidification, repaired and re-melting, resulting in duplication of electricity, a waste of energy, affecting production, resulting in more direct economic losses. The IGBT frequency will not breakdown IGBT, and complete protection. This equipment is very reliable, it can be said SCR device failure rate is one-thousandth.

2) IF furnace in the use of SCR after one year, there will be clogging waterways, fouling, handled properly it will burn out silicon, capacitors, reactors. Work found that water barrier, we must stop dealing with; while in the process, there are also repeated electrical problems, leading to loss of power and production. The IGBT device with a heat exchanger inside the recycled water is distilled water, the water does not plug fouling, greatly reducing the problem and saving maintenance costs, long-term reliable operation.

3) SCR furnace is the parallel resonant frequency circuit, the resonant circuit is current, it will make copper, cable, coil temperature rises rapidly, requiring constant row of cooling pond water plus cold water to keep the water temperature at 35 degrees to ensure the normal melting. The IGBT transistor is a series resonant circuit frequency furnace, but also voltage resonant circuit, its high resonant voltage, current, copper, cable, coil temperature is limited, often without adding cold water cooling pond cooling, saving a lot of water .

5, start-up performance: The success rate when it starts is 100%. Because it is the series resonant circuit, the inherent features like start.

Fourth, the cupola and IGBT medium frequency induction furnace in there all the advantages and disadvantages compared five, equipment installation

Power supply cabinet to be installed in a well ventilated, free from water, steam and acid gases and other attacks, non-conductive dust, no oil, gas supply room, with wall distance should be greater than 1 meter. Transit loose thread trimming, loose bolts, off the solder joints, if the cabinet or rain drenched the internal moisture, should be promptly dried.

Into the three-phase power cable firmly fixed on the cabinet power input, power transformer using three-phase four-wire, Y / Y 0 or △ / Y 0 connection, the zero line and the power supply cabinet shell grounded. Cabinet and the power output of row one end of the output bus with copper screws, cables connecting the other end with water, the distance between the bus interval of not less than 80mm. Water-cooled cable with the other end of the furnace coil pick-row connectors, water-cooled cables hanging from the lowest point total from the ground less than 100mm.

Circulating water outside the pipes out of stainless steel cabinet and out of the water and power supply port connected to the outer loop water supply pumping station and pipeline accessories owned by the user.

Mounting arrangement according to the user’s own space, workshop area, the construction process and other specific circumstances, infrastructure map for reference, provided by random water-cooled cables, copper output convergence length as shown in photo size should be determined. Furnace and the relative distance between the power supply cabinet should not be too much change.

Sixth, the use environment and conditions

1.Installation height above sea level should not exceed 1000 meters.

2.Air relative humidity of less than 80%.

3.Equipment, workplace well-ventilated, temperature can not exceed 30 ℃.

4.Equipment foundry parts of the workplace and isolation, can not make the workshop dust, powder and casting workshop corrosive gas into the interior.

5.Equipment, the workplace must ensure that no conductive dust, non-flammable, non-corrosive gases.

6.Ensure that the equipment in the absence of a strong vibration and shock indoor use.

7.Outside the cooling water temperature within +5 ~ +35 ℃, water temperature not higher than 40 ℃.

8.Cooling water pressure 0.2 ~ 0.3Mpa.

9.Cooling water between pH 6.5-7.5 PH value, water hardness not more than 8 degrees (1 degree to 1 liter of water containing 10 mg of CaO).

10.Three-phase power supply voltage fluctuations not more than 5%, not in the same workshop and SCR frequency power supply share a low-voltage lines to prevent high-order harmonic frequency of the IGBT power interference.

11.Copper output must have a high insulation board between the support intervals of not less than 80mm; copper surface with the wall insulation, distance should be greater than 100mm.

12. IGBT power supply cable must be left to place water-cooled, can not touch the ground and walls.

Seven circuit

1, the basic principles of induction heating

In alternating magnetic field inside the metal by the electromagnetic induction effect, will produce vortex. Eddy current in the metal interior for power, so that the metal temperature rising, alternating magnetic field of alternating current the greater the intensity, the greater the resulting magnetic induction, the metal will heat up faster. Using electromagnetic induction heating method of the metal has been widely used in metal smelting, diathermy, heat treatment and surface hardening. Sensor in the alternating magnetic field of alternating current in alternating current charging the metal produces heat.

2, the main circuit

a. principle of rectification control device, using the three-phase full-wave bridge rectifier, the three high-power diode and thyristor composed of three KP. Three thyristors are used as fast electronic switches, operating from the mid-frequency pulse oscillator generates a square wave pulse, the pulse transformer distribution, integer added after the thyristor gate. At this point the role of the equivalent diode thyristor bridge rectifier to achieve non-controlled rectifier, when the need to stop working or protection, the main control board blocking pulse rectifier, fast switch (thyristor) immediately disconnected.

. Furnace capacity and R, L to open into a series resonance. Series resonance in the resonant inverter circuit, the circuit impedance is minimum. The phase difference between current and voltage the greater the higher the impedance circuit. Therefore, you can adjust the phase difference between current and voltage to adjust the power output. Power regulation is regulation through the inverter main circuit to achieve the status of work, easy adjustment and flexible.

IGBT inverter control circuit with control, frequency control, power control, frequency control limit, frequency limit pressure control, the DC current limit control, frequency-current protection, DC over-current protection, ground fault protection, the upper and lower limit pressure control grid over-voltage protection, leakage protection indication furnace. The circuits are pulsed through the blockade and the IGBT gate pulse rectifier to achieve.

c. In the induction heating process, due to changes in charge impedance, the power supply in a period of time allowed to exceed the rated power. This requires the use of cut-off function. As is the current limit function within a certain range, to ensure power within the rated power operation.

Hot

Relationship between induction frequency and quenching depth (hardening depth)

waveform of DSP induction heaters

simulation of Faradays Law from University of Colorado Boulder

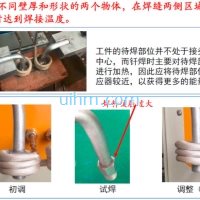

optimizing induction welding method for vehicle air conditioner

induction welding vehicle air conditioner vs common welding method

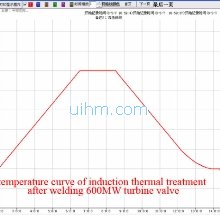

temperature curve of induction thermal treatment after welding 600MW turbine valve

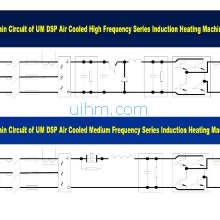

Main Circuit of UM DSP air cooled induction heaters

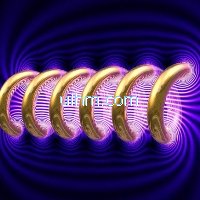

what is skin effect principle (magnetic force around induction coil)

Newest Comment

No Comment

Post Comment