Induction Heating of Flat Objects

2013/6/2 Views

this respect with the optimum heating parameters.

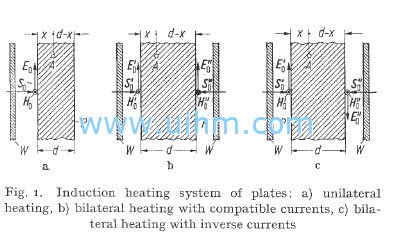

Three different induction heating systems of plates are analysed : unilateral and bilateral heating with compatible and inverse

currents. The discussion, calculation and conclusions given in the paper can be also applied in reference to plates of an irregular shape.

Ubersicht: Es ist in der Industrie ~iblich verschiedene Maschinenelemente wie Metallplatten yon unterschiedlicher Dicke mit

Frequenzen zwischen 5 ~ Hz und 3 MHz induktiv zu erw~rmen. F[lr diese Zwecke wird in diesem Aufsatz das Optimierungsproblem

yon Erw/irmungsparametern betrachtet. Es werden drei verschiedene Induktionserw~rmungssysteme von Platten analysiert: ein- und zweiseitige Erw/~rmung dutch gleich- und entgegengerichtete Str6me. Die angegebenen Betrachtungen,

Berechnungen und Ergebnisse k6nnen auch auf die Induktionserw~rmung von zylindrischen Platten angewendet werden.

1. Introduction

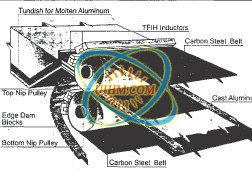

Inductive heating very often means heating fiat objects, e.g. metal plates of different thickness.

These are usually elements which are heated with a frequency within the range 5o Hz to 3 MHz, either thoroughly with respect to the plastic working or to the heat treatment of the metal element, or are heated on the surface only for the purpose of hardening.

Flat metal objects as well as those of a cylindrical shape which are also frequently used are the typical machine elements used in induction heating.

All the other possible shapes of objects can be nearly always reduced in theoretical and technical consideration to a flat or a cylindrical shape.

The elements in question are mostly objects of mass industrial production for which the problem of heat treatment and induction heating must be solved in the best possible way, i.e. with the optimum heating parameters with regard to the thermal process itself, or because of economic and technical aspects of the heating process, e.g. high heating rate,

minimum electric energy consumption, required temperature distribution, etc.

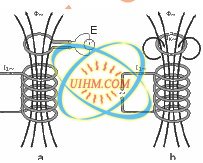

It is common "practice in industry to heat flat objects unilaterally or bilaterally by induction i.e. by means of an appropriately shaped heating inductor

which is applied to one side of the heated object, or by means of two inductors applied to both sides of it.

The inductors are the source of an electromagnetic wave which penetrates the surface of the heated object, supplying the electric energy converted into heat.

The electromagnetic field which has been generated in this way is characterized by the three vectors: tile intensity of the magnetic field H, of the electric fieldE, and by the Poynting vectorS.

The corresponding induction system with the inductor w and with the three vectors marked on the surface of a flat object p of a thickness d are shown schematically

Down Attachment

- DownloadAttach1: induction heating of flat objects.pdf Clicks

Good

Bad

Newest Comment

No Comment

Post Comment