Induction Hot Forging

Views Send Enquiry

Forging can be defined as a manufacturing process, which involves heating and pressing a metal at a high temperature into stronger parts. Hammers, presses and upsetters are the equipments used in the forging process. Some of the metals that can be forged include brass, copper and aluminum. Brass forgings and copper forgings that are component parts are used in mining equipment, missiles, engines, automobiles, ships and airplanes and much more.The forged parts have superior density and they are also free from any flaws. Each of the metals varies from one another in regards to the weight characteristics and strength. Brass forgings and copper forgings are different from mold casting, which involves melting of the metal and pouring it into molds. Forging process has numerous advantages and the forged parts have improved tolerance capabilities and the ability to be processed further by automated methods. Advancement in forging technology helps in meeting the design and performance requirements. No other process can beat forging when it comes to strength and reliability. The types of brass forgings and copper forgings include impression die forging, cold forging and open die forging. The most basic method used for forging parts is Impression die forging which is otherwise known as closed die forging. The metal part is heated and formed into a predetermined shape with the help of dies. The metal is then shaped with the help of forging process to improvise physical and mechanical characteristics of the parts. Hammers, mechanical and hydraulic presses are used in closed die forging method. In the modern era, forging process is done with the help of high-speed automatic equipment. Due to this, the cost is reduced and there is also less wastage. The impression die forging or the closed die forging helps in yielding various complex shapes which include both symmetrical and non symmetrical. This is possible because the die cavity restricts the metal flow. Savings can be maximized on huge production of forged parts. Copper forgings and brass forgings offer numerous advantages over the other processes. Copper or brass undergoes tremendous pressure during forging as well as rod extrusion. Leak resistance and close tolerance of the forged parts are the other advantages. The forged parts also get a clean and lustrous appearance. The company, which deals with forgings, keeps exploring new methods to meet the requirements of the customers. Industries dealing in brass forgings and copper forgings make parts that work efficiently. These industries make parts not only for their customers but also for their own internal use. With the implementation of modern technology the turn over time for delivering products is really quick. Six sigma methodologies are adopted by the world class manufacturing industries to provide forged parts, which are of better quality, and to reduce costs and wastes. The forging process carried out by a well-established forging company prevents the parts from metallurgical defects. The forged parts undergo various processes such as trimming, washing and finishing after which these parts are given a final touch as they undergo the polishing process. The various processes employed in making the forged parts enable in shortening the lead-time as well as adapt to various production run lengths. The forged parts resulting out of the forging processes are perfectly dimensioned.

Forging is a process, in which metals are shaped by applying compressive forces on it. Forging process classification is done on the basis of temperature into cold, hot forging or hot treatment. In olden days forging was done by smith with the help of hammer and anvil. But now with the advent of technology and engineering process traditional forging is done by compressed air, hydraulics machines, hammer press and steam. Forging is very reliable in comparison to casting, fabrication, welding, machined bars and other metal shaping process. Hot forging and cold forging are the different ways of processing with the metals but they provide up with the same results. There are many metal processing experts in the market but emtmftm is one stop solution for all your metal forging needs. Let us discuss how the forging processes are done: The piece of metal is provided with the hot treatment at certain temperature levels and depends upon the type of metal for eg: 1100-1150 degrees for steel 350-520- degrees for Aluminum alloys710-800 degrees for Copper alloys During this process the temperature is above the recrystallization point of that metal, which provides the metal with the strain-hardening effects, the advantages and disadvantages of hot forging Advantages* Increase in ductile strength * High temperature helps in removal of homogeneous substances due to increased diffusion * Reduction in the pore sizeDisadvantages* Lesser tolerance * Warping of material during the cooling process * Undesirable result due to reaction of metal with that of surroundings * Varied metal structureCold Forging is defined as a process where metal is below recrystallization pointThis process is an inexpensive process compared to hot treatment process .This treatment is used on soft metals like aluminum and copper. Cold forging is done at room temperature and a common method used in this process is impression-die forging, where metal is placed into a die , which is attached to an anvil , and the hammer is forcefully dropped on the metal piece, resulting into the flow of metal and it get filled into the die spaces . Advantages Cold forging is preferred over hot forging as cold forged parts require no finishing work or a very less work, this step in the fabrication process is very cost effective. Cold forging has less impurities and results into smooth shiny surface. Disadvantages * Less ductile metal* Heavy and powerful machinery is needed* Very strong tools are needed* Residual stress * The surface of the metal is to be cleaned before the process starts

hot forging process

Hot

Relationship between induction frequency and quenching depth (hardening depth)

waveform of DSP induction heaters

simulation of Faradays Law from University of Colorado Boulder

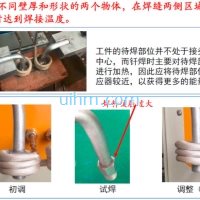

optimizing induction welding method for vehicle air conditioner

induction welding vehicle air conditioner vs common welding method

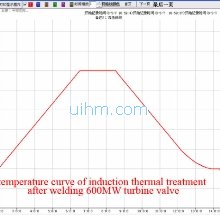

temperature curve of induction thermal treatment after welding 600MW turbine valve

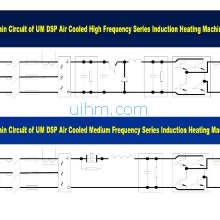

Main Circuit of UM DSP air cooled induction heaters

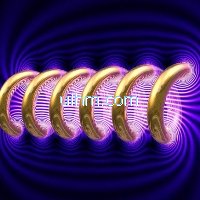

what is skin effect principle (magnetic force around induction coil)

Newest Comment

No Comment

Post Comment