What is induction heat treatment

Views Send Enquiry

eat treatment of metal is a method of manipulating the metal (in terms of its physical properties) to achieve the operational condition of the metal—both for machining and then for operation. Most metals can be made to be soft or hard, or tough or wear-resistant or both tough and wear-resistant. They also can be made to reduce the possibility of corrosion or they can be made to be soft. This is all done with the application of heat to the metal.

There are many definitions of metals:

- Metals are a group of elements in individual form such as tin, gold, silver, iron, aluminum, chromium, vanadium, etc.

- Metals usually are very dense and good conductors of heat.

- Metals are usually malleable and easily manipulated. They can easily be polished to a shiny surface finish.

In our case metals are usually alloyed with other elements to change the physical condition of the metal, such as, iron with carbon to make simple steels and copper with zinc to make simple brass. There are many combinations of mixtures of metal elements to give equally, many different characteristics. The metals groups can be divided into two distinct categories .

It can be seen from the tree that we have focused only on steels (ferrous) and other metals (non ferrous). In this series we will be focusing on the ferrous group of metals (steels).

Heat treating is a core manufacturing competency and can best be defined as “the controlled application of time, temperature and atmosphere to produce a predictable change in the internal structure (i.e. microstructure) of a material.” Thus, metallurgists are responsible to predict the microstructural changes that will occur in a component, while heat treaters are responsible for controlling the process and equipment variables so that the desired outcome will be achieved.

Heat treating allows us to vary the properties (mechanical, physical, metallurgical) of a given material to optimize its design performance. We heat treat, therefore, quite literally because we must. It is the most cost-effective way to achieve the desired outcome. One of the greatest challenges we face as heat treaters is that the same flexibility that allows us to manipulate the end result of a heat treatment, tests our ability to control and repeat our processes to achieve our customer’s desired product performance time after time.

Heat treating is a vital part of manufacturing. Thus, it is critical for any organization that relies on this technology to understand the relationship that exists between the variables that influence product response to heat treatment; namely material choice, properties, part design, manufacturing practices and heat-treating methods. This relationship is best illustrated by the Model of Material Science.

The model is intended to help us understand the inter-relationship between each technology link. Just as a chain is only as strong as its weakest link, so too is the success of a heat-treatment operation dependent on proper execution of each phase of the model. The model explains how to achieve results using both the older philosophy (discovery-based methodology) and the newer approach (scientific-based) methodology.

The scientific- or engineering-based methodology (down arrow) starts by considering the needs of the end user, that is the performance demands of a specific product, which, in turn, requires the design engineer to select a material capable of achieving certain mechanical, physical and metallurgical properties. These properties can only be developed in the selected material by producing the correct microstructure that in turn dictates a particular heat-treatment process or series of processes be run in a specific piece of equipment.

The discovery or trial-and-error methodology (up arrow) begins with material selection. It involves using a specific piece of equipment to run a heat-treatment process or series of processes, thus producing a specific microstructure in the material, which, in turn, determines the mechanical, physical and metallurgical properties that the material will achieve and ultimately defines the end-use performance capability of the product.

A good example of using this methodology is the range of products and services used in the most demanding service applications. The Apache helicopter, for example, is a unique fighting platform, one that places the highest demand on each subsystem including the transmission, engines and weapons platform. The heat-treating challenges are obvious to ensure that each flight system is optimized. This type of challenge underscores the need to optimize our processes and to ensure that our equipment is under total control.

Many metalworking operations (e.g., grinding, stamping, rolling, forming, machining and plating) shape, size or produce finishes on metals, but only heat treating can significantly change the ultimate condition (physical, mechanical, metallurgical) of these shapes. Virtually all materials can have their properties enhanced by heat treatment.

Many heat-treating operations fall into two basic categories: softening (e.g., annealing, normalizing) and hardening (e.g., through hardening, case hardening). Softening removes stresses, refines grain structure and puts a material in a workable condition for subsequent operations. Hardening often improves surface hardness and wear resistance, increases toughness and improves resistance to impact so that the final product is a useful engineering material.

Heat Treatment is the controlled heating and cooling of metals to alter their physical and mechanical properties without changing the product shape. Heat treatment is sometimes done inadvertently due to manufacturing processes that either heat or cool the metal such as welding or forming.

Heat Treatment is often associated with increasing the strength of material, but it can also be used to alter certain manufacturability objectives such as improve machining, improve formability, restore ductility after a cold working operation. Thus it is a very enabling manufacturing process that can not only help other manufacturing process, but can also improve product performance by increasing strength or other desirable characteristics.

Simple Heat Treatment Metallurgy

The heat treatment of any steel simply means that you will apply heat to the steel to raise it to a required temperature and then cool it down in an appropriate manner. demonstrates the heat treatment process. The schematic illustrates a simple process of heat up, soak at temperature and cool down, which represents the basic schematic for every type of heat treatment that one can think of—including surface treatment processes. Heat treatment is used to make the steel soft for machining and manipulation, and then into the final metallurgy necessary for the steel to function in its particular environment.

induction heat treatment

Hot

Relationship between induction frequency and quenching depth (hardening depth)

waveform of DSP induction heaters

simulation of Faradays Law from University of Colorado Boulder

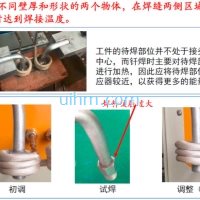

optimizing induction welding method for vehicle air conditioner

induction welding vehicle air conditioner vs common welding method

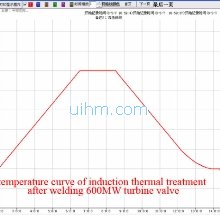

temperature curve of induction thermal treatment after welding 600MW turbine valve

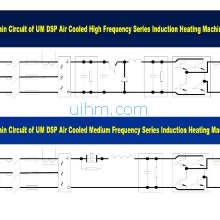

Main Circuit of UM DSP air cooled induction heaters

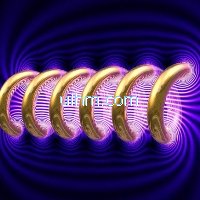

what is skin effect principle (magnetic force around induction coil)

Newest Comment

No Comment

Post Comment