-

Keywords"Induction Heating",total

536 records

-

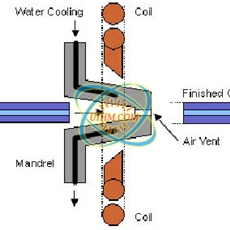

Induction Heating brass mandrel die

Heating brass mandrel die Objective Water-cooled brass mandrel die, nylon LDPE catheter, “K” type thermocouple and temperature controller. Material materials, supplies involved in the application Temperature 400F (204C) Frequency 325kHz Equipment…

-

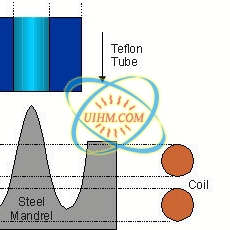

Induction Heating steel mandrel tip

Heating steel mandrel tip Objective Heat a water-cooled steel mandrel to 700F (371C) to form a high quality Teflon catheter tip.Material Teflon catheter tubing, mandrel assemblyTemperature 600-700F (315-371C)Frequency 376 kHzEquipment • Power of 10kW indu…

-

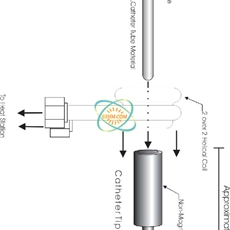

Induction Heating catheter tipping die

Heating Catheter Tipping Die Objective: To heat an aluminum catheter tipping die to above 2850F within 2 to 5 seconds for the forming of catheter material. Presently, heating is performed in 15 seconds with older induction equipment. The customer would lik…

-

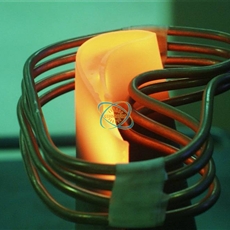

Induction Heating fan blades for welding

Heating fan blades for welding Objective To uniformly heat jet engine turbine fan blades to 1800F (982.2C) within five minutes for a welding applicationMaterial Jet engine turbine fan blades with 2”(50.8mm) length tipTemperature 1800F (982.2C)Frequency 21…

-

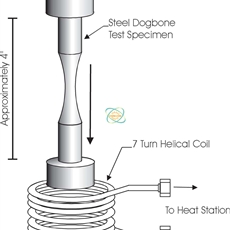

Induction Heating steel dogbone specimen

Heating Steel Dogbone Specimen Objective: To heat a magnetic steel dogbone specimen to 12000F as quickly as possible and sustained for tensile testing. Heating should take place using a helical coil placed square in relation to the long axis of the gage ar…

-

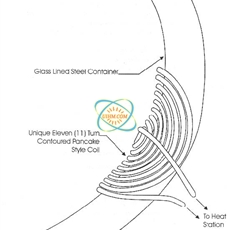

Induction Heating repair lined steel tank

Heating Repair Lined Steel Tank Objective: To heat selected areas of a glass lined steel tank to 16000F in order to perform repairs of cracks and chips. The glass is used as a frit which must be reflowed and filled into the damaged areas. Temperature contr…

-

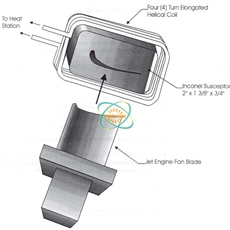

Induction Heating inconnel susceptor

Heating Inconnel Susceptor Objective: Heat an Inconnel susceptor to 19500F in less than one (1) minute for heating jet engine fan blades. This approach is to be used, instead of directly heating the blade, since improved temperature uniformity will be achi…

-

heat treatment with Induction Heating of within pipes

HEAT TREATMENT WITH INDUCTION HEATING OF WITHIN PIPES Electrically welded pipes with an external diameter of 16-102 mm made from corrosionresistantsteels of the austenitic class after having been made on argon-arc welding mill(AAW) are at present heat-trea…

-

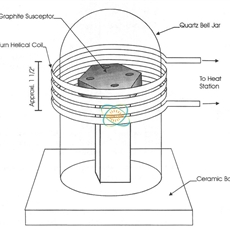

Induction Heating graphite susceptor

Heating Graphite Susceptor Heating Graphite SusceptorObjectiveTo Heat a graphite susceptor to 1100C in an inert atmosphere of Nitrogen and Hydrogen. The susceptor is to be used for metal oxide chemical vapor deposition (MOCVD) crystal growth experiments. V…

-

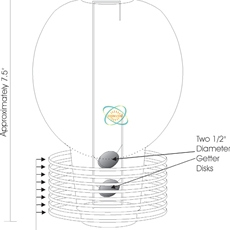

Induction Heating light bulbs

Objective To heat two 0.5″ getters to a red glow inside a light bulb in order to fire the getters within 8 seconds. Presently the bulbs are lowered onto an eight station turnstile with an index time of 8 seconds. Material Metal Halide Lamp containing …