-

Keywords"Induction Heating",total

536 records

-

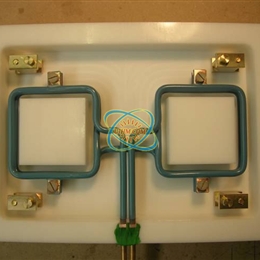

Induction Heating motor

Heating motor Objective Heat steel to help bond an injection molded piece and help the reflow.Material Steel motor body, 60 x 60 x 27 (2.4 x 2.4 x 1.1) mm(in)Temperature 260C (500F)Frequency 237 kHzEquipment • Power of 20kW induction heating system, equip…

-

Induction Heating steel rivets

Heating steel rivets Objective Heating steel rivets prior to head formingMaterial steelTemperature 1292 F (700C)Frequency 83 kHzEquipment • Power of 7 kW induction heating system, equipped with a remote workhead containing one 1.5μF capacitor.• An induc…

-

Induction Heating engine head

Heating engine head Objective Heat steel liners on the head of an engine to remove aluminium casing. Material Steel, 80 mm ID x 190 mm (3.1 in x 7.5 in.) Temperature 650 C (1202 F) Frequency 81 kHz Equipment Power of 35kW induction heating system, …

-

Induction Heating aluminium susceptor

Heating aluminium susceptor Objective Expand powder into solid form for use in crash helmetsMaterial Microspheric powderAluminium chamber 110mm (4.3 in.) diameter x 35mm (1.3 in.) deep used to hold powderTemperature 150 oC (302 oF)Frequency 54.5 kHzProcess…

-

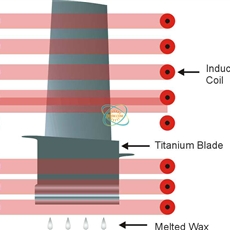

Induction Heating titanium blade

Heating Titanium Blade Objective Heat a titanium blade to 500F (200C) to melt and drain the wax from inside the blade.Material 4” length (101.6mm) titanium blades with 1.5” x 0.25” (38.1mm x 6.4mm) metering areaTemperature 500F (200C)Frequency 186 kHzEq…

-

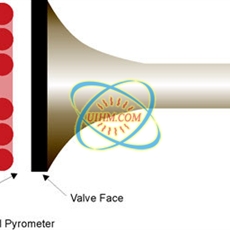

Induction Heating engine valve

Heating Engine Valve Objective To heat the face of an engine valve head to 900F and maintain the temperature for an extended time, hightemperature stress test.Material Engine valve head (two sizes), temperature sensing paintTemperature 900 FFrequency 223 k…

-

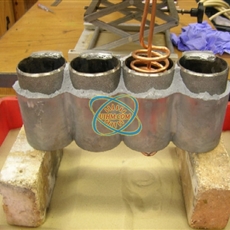

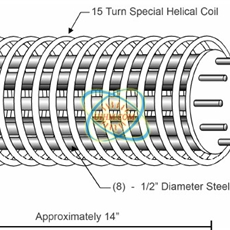

Induction Heating eight steel rods

Heating Eight Steel Rods Objective Heat eight steel rods simultaneously to 212F (100C) for a molding operation.Material 8 Steel Rods measuring 1/2 (12.7mm) in diameter and 14 (355.6mm) long held in place by 2.5” (63.5mm) diameter Teflon end plates.Tempera…

-

Induction Heating carbon graphite anodes

Heating carbon graphite anodes Objective Heating carbon graphite anodes to destructively oxidize the parts to process embedded contaminantsMaterial anodes 2.5 x 2.5 x 4 (63 x 63 x 102) h x w x d in (mm)Temperature 1900 F 1000CFrequency 54 kHzEquipment Powe…

-

induction silver brazing with Induction Heating

silver brazing with induction heatingInduction Silver brazing actually uses not pure silver, but instead a silver alloy containing nonferrous metal to bond two pieces of metal together. The process is typically used to join close-fitting parts that require…

-

induction silver soldering with Induction Heating

Silver soldering with induction heating A full treatise on silver soldering (otherwise known as hard soldering) would be an extensive document, and all I want to cover here is the basics. A serious job such as constructing a model locomotive boiler require…