-

Keywords"induction",total 2890 records

-

what is induction hardening

induction hardeningPrincipal methodsSingle shot hardeningIn single shot systems the component is held statically or rotated in the coil and the whole area to be treated is heated simultaneously for a pre-set time followed by either a flood quench or a drop…

Date:2008/02/03

-

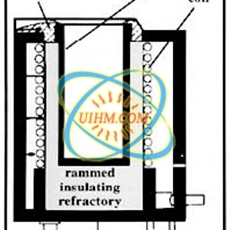

crucibles for induction melting

Crucibles for Induction MeltingThe proper crucible for melting of ferrous alloys is often viewed as a insignificant decision when, in reality, considerable effort should be given to this important decision. Crucible performance can have dramatic effects on…

Date:2008/02/03

-

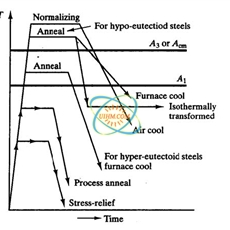

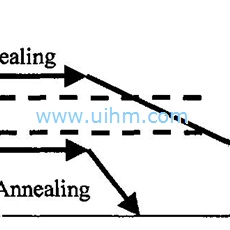

induction heat treatment of steels

Heat Treating is the process of heating and cooling a steel to obtain desired properties.Various types of heat treatment processes are used to change the following properties or conditionsof the steel:- Improve the toughness – Improve the machinability- I…

Date:2008/02/03

-

induction heat treatment process

Heat Treatment process HEAT TREATMENTWe use heat treatments to change properties of metal, or as a method of controlling formation of structures, or expansion/contractional^forces during welding. In heat treating metals and alloys there are many elements f…

Date:2008/02/03

-

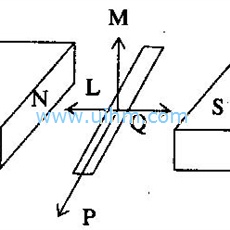

electromagnetic induction

Electromagnetic Induction electromagnetic inductionElectromagnetic induction and Faradays experimentsE.M. induction is the phenomenon of production of induced electric current and induced e.m.f in aconducting loop whenever the magnetic flux linked with the…

Date:2008/02/03

-

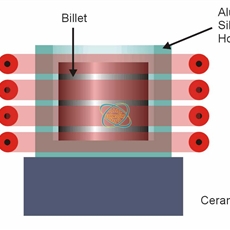

induction forging inconel billets

Forging Inconel Billets Objective To heat inconel billets to 2050F (1121.1C) for a forging process.Material Small inconel billets 0.39” OD, 0.7” length (.99mm OD, 17.8mm length) with ceramic crucible 1.0” OD, 0.7” ID, 1.4” length (25.4mm OD, 17.8mm ID…

Date:2008/02/03

-

what is induction heat treatment

What is heat treatment eat treatment of metal is a method of manipulating the metal (in terms of its physical properties) to achieve the operational condition of the metal—both for machining and then for operation. Most metals can be made to be soft or ha…

Date:2008/02/03

-

how induction brazing works

How Induction Brazing Works Induction brazing is a process where two or more materials such as pipe are joined together with a molten space filler metal using an induction heating coil which delivers a very high temperature. The induction brazing process w…

Date:2008/02/03

-

induction silver soldering

Silver Soldering Soldering is the process in which two or more metal items are fused or joined together usually using flux & solder with heat as a catalyst. To solder silver findings to jewellery, such as a catch or pendant to a chain, certain procedur…

Date:2008/02/03

-

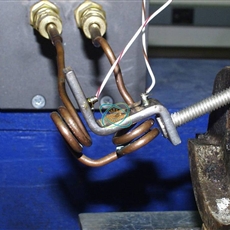

induction soldering copper wires

Soldering copper wires Objective Soldering two copper wires to pre-installed turrets on a copper buss barMaterial Solder dipped copper/nickel buss bar, 2 tinned stranded copper wires, brazing stickTemperature 446 F (230 C)Frequency 230 kHzEquipment •Power…

Date:2008/02/03

© Copyright 2025. uihm.com All Rights Reserved.