-

Keywords"in",total 3005 records

-

electromagnetic induction and the joule effect

Induction Heating has the important characteristic that the heat is generated in the material to be heated itself. Principle of induction heatingBecause of this, induction has a number of intrinsic trumps, such as a very quick response and a good effici…

Date:2006/10/02

-

induction annealing locknuts

Objective To heat locknuts to 2150F (1176C) for annealingMaterial Waspaloy locknutTemperature 2150F (1176C)Frequency 382 kHzEquipment • UM-10AB-UHF induction heating system, equipped with a remote workhead containing one 0.66μF capacitor.• An induction …

Date:2006/10/02

-

induction annealing metal stamp sets

Objective Heat the opposite end of a metal stamp so that it mushrooms instead of cracks/splits when struck by a hammer.Material S-7 steel of varying rectangular cross sectional sizesTemperature 1400-1800 F (760-982) CFrequency 204-165 kHzEquipment 25 kW, i…

Date:2006/10/02

-

induction annealing saw blades

Objective Anneal saw blades used for cutting bread, prior to hole punching.Material .38” (9.6mm) wide and .51” (12.9mm) wide continuous strips of 400 series stainless steel.Temperature 600C (315.6F) for one secondFrequency 229kHzEquipment • UIHM 6 kW i…

Date:2006/10/02

-

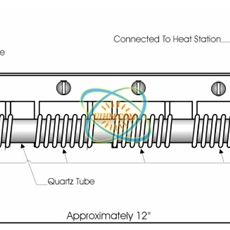

induction annealing tungsten rods

Objective To heat customer-supplied rods of various diameters (0.14 inch to 0.49 inch) to 4170F (2300C) at 2-4 feet per minute Material Tungsten and Molybdenum; Tests are run in an atmosphere of Nitrogen or Hydrogen avoid oxidation of the materials. Temp…

Date:2006/10/02

-

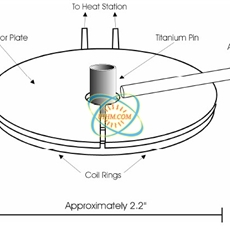

induction annealing titanium fasteners

Objective Heating a titanium fastener to 1100-1450F (593-788C) for an annealing process. Material 0.06” (1.5mm) high zone on a titanium fastener measuring 0.163-0.375” (4.14-9.52mm) in diameter and 0.5-3.0” (12.7-76.2mm) in length Temperature 1100-145…

Date:2006/10/02

-

induction annealing brazing wire

Objective: Anneal a brazing wire for preform production. Material :Copper Nickel Silver 2774 Alloy rod 0.070″ (1.8mm) diameter. Temperature 650F(343.3C) Frequency 281 kHz Equipment • UM-06A-UHF induction heating system equipped with a remote workhead…

Date:2006/10/02

-

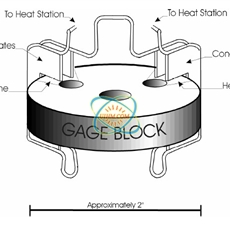

induction annealing thread ring

Objective: To selectively and uniformly anneal two sections of a thread ring gage block from the hole to the outside surface from a hardness of Rc 59-61 to Rc 45. The gage blocks are made from O6 steel and range in size from 1″ to 8 1/2″ in …

Date:2006/10/02

-

principle of induction heating (induction heating principle)

induction-heatingINDUCTION HEATING was first noted when it was found that heat was produced in transformer and motor windings, as mentioned in the Chapter “Heat Treating of Metal” in this book. Accordingly, the Principle of induction heating was studied …

Date:2006/03/30

-

induction bending and hot rolling

Induction Bending And Hot Rolling the 1620mmX40mm steel pipe in the West-East natural gas transmission project. Induction bending is also referred to as hot rolling, but there are some differences between the two processes. Induction bending is an ef…

Date:2006/03/30

© Copyright 2025. uihm.com All Rights Reserved.