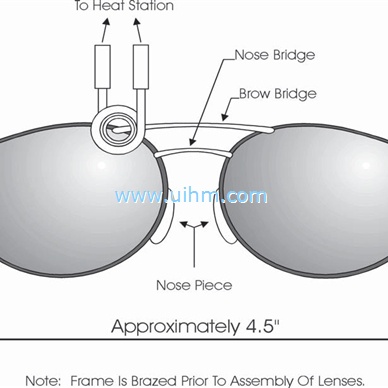

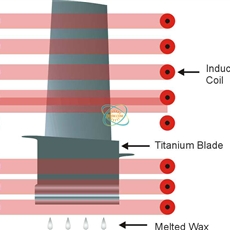

Induction Heating Titanium Blade Class: Induction Heat Treatment

Induction Heating Titanium Blade Class: Induction Heat Treatment Intro: Heating Titanium Blade Objective Heat a titanium blade to 500F (200C) to melt and drain the wax from inside the blade.Material 4” length (101.6mm) titanium blades with 1.5” x 0.25” (38.1mm x 6.4mm) metering areaTemperature 500F (200C)Frequency 186 …

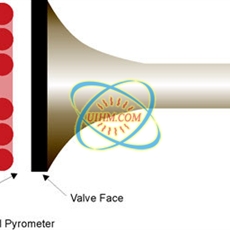

Induction Heating Engine Valve Class: Other Induction Applications

Induction Heating Engine Valve Class: Other Induction Applications Intro: Heating Engine Valve Objective To heat the face of an engine valve head to 900F and maintain the temperature for an extended time, hightemperature stress test.Material Engine valve head (two sizes), temperature sensing paintTemperature 900 FFrequency …

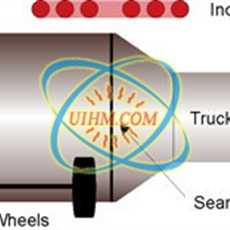

Induction Pre-heating Truck Axle Class: Induction Tempering or Preheating

Induction Pre-heating Truck Axle Class: Induction Tempering or Preheating Intro: Pre-heating Truck Axle Objective To pre-heat the seam of a truck axle to over 300F within 15 seconds for a welding application and maintain temperature within the welding zone for 15 seconds after the power isturned off.Material Steel truck axle; 350 …

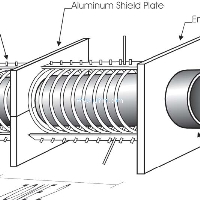

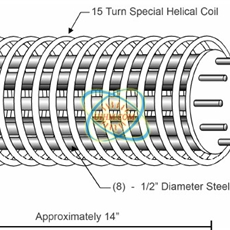

Induction Heating Eight Steel Rods Class: Other Induction Applications

Induction Heating Eight Steel Rods Class: Other Induction Applications Intro: Heating Eight Steel Rods Objective Heat eight steel rods simultaneously to 212F (100C) for a molding operation.Material 8 Steel Rods measuring 1/2 (12.7mm) in diameter and 14 (355.6mm) long held in place by 2.5” (63.5mm) diameter Teflon end plates.Te…

Induction Melting Furnaces Class: High Capacity Melting

Induction Melting Furnaces Class: High Capacity Melting Intro: Melting FurnacesCharacteristics of cast iron to a large extent depend on the content of harmful impurities and, above all, of sulfur. For modifications to the high-strength nodular cast iron should have a low sulfur content. In cupola furnaces to smel…

Induction Heating carbon graphite anodes Class: Other Induction Applications

Induction Heating carbon graphite anodes Class: Other Induction Applications Intro: Heating carbon graphite anodes Objective Heating carbon graphite anodes to destructively oxidize the parts to process embedded contaminantsMaterial anodes 2.5 x 2.5 x 4 (63 x 63 x 102) h x w x d in (mm)Temperature 1900 F 1000CFrequency 54 kHzEquipment…

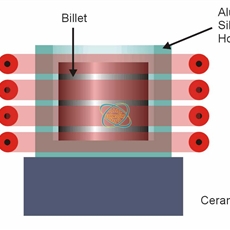

Induction Forging Inconel Billets Class: MF Induction Forging

Induction Forging Inconel Billets Class: MF Induction Forging Intro: Forging Inconel Billets Objective To heat inconel billets to 2050F (1121.1C) for a forging process.Material Small inconel billets 0.39” OD, 0.7” length (.99mm OD, 17.8mm length) with ceramic crucible 1.0” OD, 0.7” ID, 1.4” length (25.4mm OD, 17.8…

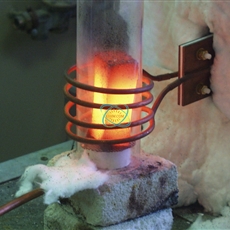

Induction Silver Soldering Class: Induction Soldering

Induction Silver Soldering Class: Induction Soldering Intro: Silver Soldering Soldering is the process in which two or more metal items are fused or joined together usually using flux & solder with heat as a catalyst. To solder silver findings to jewellery, such as a catch or pendant to a chain, certain pro…

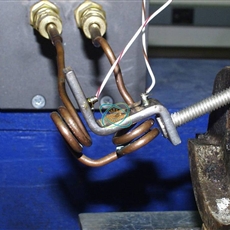

Induction Soldering copper wires Class: Induction Soldering

Induction Soldering copper wires Class: Induction Soldering Intro: Soldering copper wires Objective Soldering two copper wires to pre-installed turrets on a copper buss barMaterial Solder dipped copper/nickel buss bar, 2 tinned stranded copper wires, brazing stickTemperature 446 F (230 C)Frequency 230 kHzEquipment •…

Induction silver brazing with induction heating Class: HF Induction Brazing

Induction silver brazing with induction heating Class: HF Induction Brazing Intro: silver brazing with induction heatingInduction Silver brazing actually uses not pure silver, but instead a silver alloy containing nonferrous metal to bond two pieces of metal together. The process is typically used to join close-fitting parts that re…

Recommended

induction brazing diamond segment

induction shrink fitting for Automotive cylinder rod

induction heating drill pipe by twin coils

Ball stud high-frequency induction hardening

Splined shaft induction hardening

Sprocket induction hardening

Gear shaft induction hardening

High frequency induction brazing welding steel bar