Cadmium in silver soldering or brazing

2013/5/16 Views

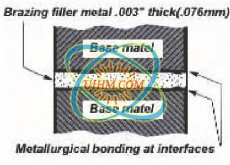

Silver (hard) soldering or brazing is a very versatile means of making joints by using a fusible alloy as a filler material between similar or dissimilar parent materials.

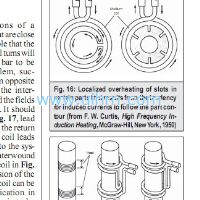

Temperatures above 620°C are applied, usually by handheld flame torch or another heating device, eg induction

or electrical heater/furnace, to melt the filler material into a capillary gap between the parent materials and create

a suitable bond.

Such joints are invariably leak proof, will withstand vibration, tensile and torsional loading, and maintain integrity at both sub-zero and elevated temperatures.

When well selected and applied, they can also resist attack to a wide range of corrosive environments.

Because of these excellent properties and ability to join dissimilar materials, silver solder alloys are used in practically every branch of the metal fabrication industry.

Temperatures above 620°C are applied, usually by handheld flame torch or another heating device, eg induction

or electrical heater/furnace, to melt the filler material into a capillary gap between the parent materials and create

a suitable bond.

Such joints are invariably leak proof, will withstand vibration, tensile and torsional loading, and maintain integrity at both sub-zero and elevated temperatures.

When well selected and applied, they can also resist attack to a wide range of corrosive environments.

Because of these excellent properties and ability to join dissimilar materials, silver solder alloys are used in practically every branch of the metal fabrication industry.

Down Attachment

- DownloadAttach1: Cadmium in silver soldering or brazing.pdf Clicks

Good

Bad

Newest Comment

No Comment

Post Comment